Micro-g Update 2020 posted in microg

April 23, 2020

NASA’s Micro-g NExT Challenge is an annual competition for undergraduate students to design, build, and test tools that address current space exploration challenges faced by astronauts in microgravity environments. This year, the challenges all focused on aspects of the Artemis program—NASA’s upcoming lunar mission—to address issues such as sample collection and dust tolerance in a lunar environment.

CSI’s 2020 Micro-g NExT team, Lion Core, participated in the Lunar Sample Coring Device project proposed by NASA’s Jet Propulsion Laboratory, designing a drill bit to collect core samples of lunar regolith. We began the design process in early September 2019, focusing our attention on designing a drill bit that could interface with NASA’s underwater diving drill and capture a pristine sample of either concrete or ice as per the challenge guidelines. Because our final tool is dive-tested at the Neutral Buoyancy Laboratory in Houston, TX each year, we worked to additionally ensure our coring drill bit could operate underwater and be easily used in a simulated lunar (1/6th gravity) environment.

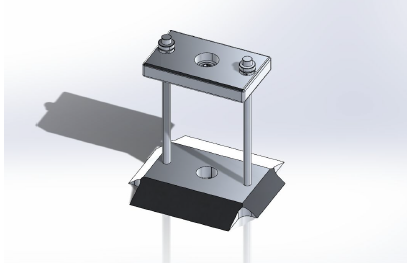

After two months of work on our design, we created the Handheld Assistive Removal Device to Capture Observable Regolith Elements (or HARDCORE for short.) HARDCORE consists of (1) a coring drill bit that can capture core samples of 0.5” in diameter and 3” deep and (2) a stabilization jig that allows for easier core extraction in the lunar gravity environment. We submitted a proposal to NASA outlining the design and intended operation at the end of October 2019 and were selected as finalists in early December to manufacture our device and test it in the NBL.

Since submitting our proposal and hearing of our finalist status in the competition, our team has been hard at work updating our design, manufacturing our device, and testing prototypes in the Columbia Makerspace and Mechanical Engineering Shop. Our initial coring bit testing yielded promising results, with the drill bit able to capture a core sample from ice. We have since updated our design to assist in capturing a more pristine sample and streamlined our stabilization jig design to be lighter and more stable.

We have been continuing to make steady progress with our design updates and prototype manufacturing, despite being dispersed around the continent due to COVID-19. Our team now meets virtually and will continue our manufacturing process over the summer with the goal of sending our final tool to the NBL for remote testing in early September!

– Micro-g Team

Liked that post? Check out the news page