Photo: NASA

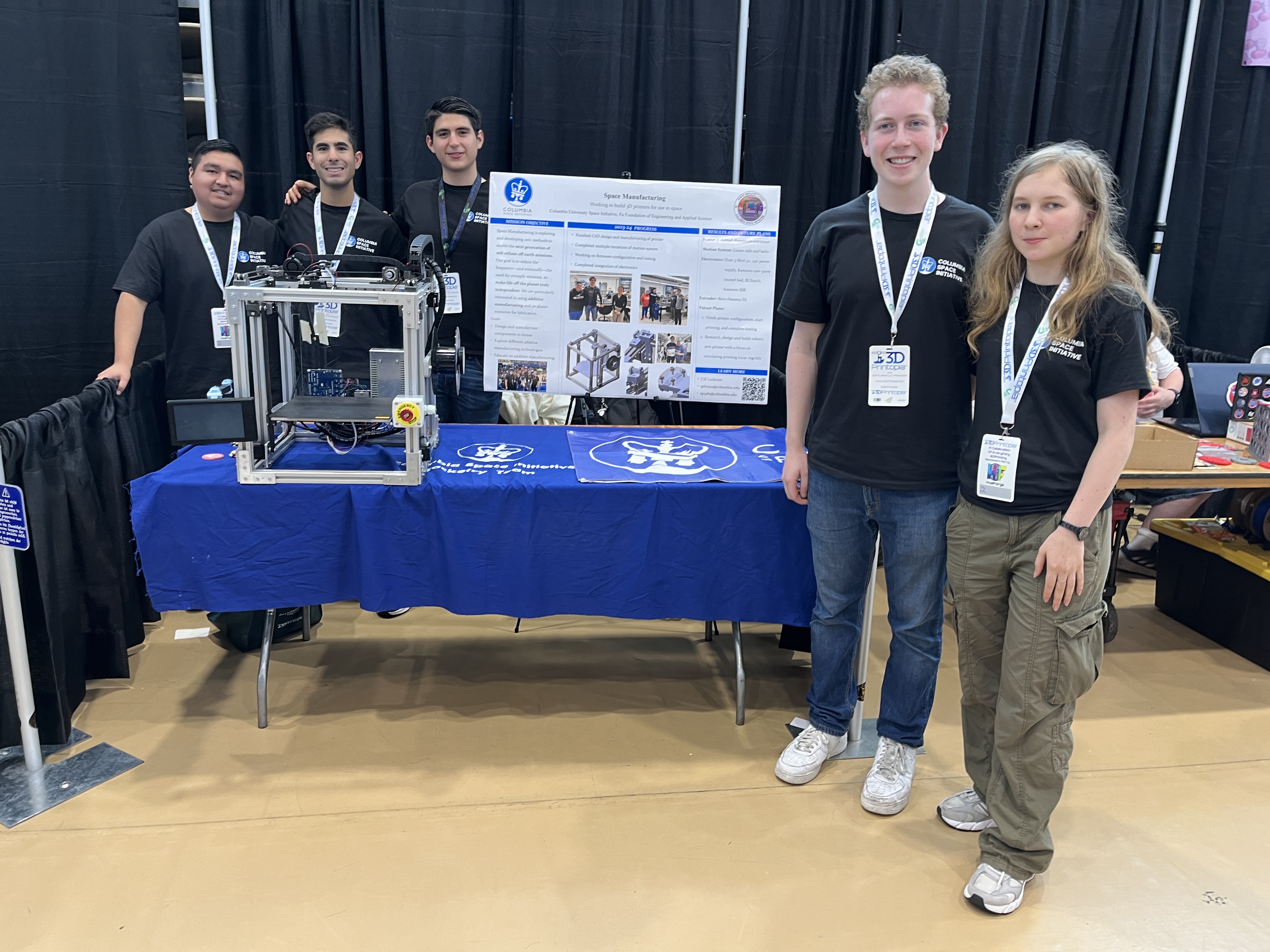

Space Manufacturing traveled to Bel Air, Maryland September 28th to present their novel 3D printer at 3DPrintopia (formerly East Coast Rep Rap Festival). 3DPrintopia is a conference and celebration of everything 3D printing. Industry leaders, individual makers, and companies presented innovative 3D printers, materials, and the latest in 3D printing technology. A wide range of projects ranging from novel multi material filaments to diamond tipped nozzles were shared.

CSI’s Space Manufacturing mission is exploring and developing new methods to enable the next generation of self-reliant off earth missions. For the past two years the mission has been designing and manufacturing a novel 3D printer that was unveiled to the wider 3D printing community at 3DPrintopia. Attendees were interested in the printer’s design and applications. The team received valuable feedback ranging from the electronics for use in space to frame construction. The team was especially excited to connect with the founder of Prusa, Joseph Prusa and other industry representatives including E3D, LDO Motors, KB3D, Freepeeko, among others.

After a great time learning from fellow 3D printing enthusiasts’ projects and feedback, Space Manufacturing is ready to tackle its next objective: developing a novel printer to print lunar regolith!

The trip was a great success and we hope to return next year!

– Space Manufacturing Team

This August, CSI’s Outreach team conducted the Space Science Program at Sophie Gerson Healthy Youth’s yearly summer camp, where we ran rocket launches and observational astronomy sessions, taught students to fly drones and make simple electric circuits, hosted space-themed jeopardy, and challenged students to engineer in creative ways! Our six space science counselors set up and ran these activities for 140 middle school students over the course of the week-long camp. Some activities were familiar to the students, because Outreach had run them during Auditorium Programs at their schools. However, some were completely new—including the constellations circuits activity, which debuted at the camp this year to great success!

The circuits activity challenges students (and willing Camp Zeke Counselors!) to create a circuit using conductive copper tape and a coin battery to light up an LED. In preparation for this activity, CSI had ordered the materials necessary, but the night before the scheduled day of the activity, we realized we were missing a crucial piece—the 500 LED lights we ordered. After all space science counselors searched high and low, former Outreach directors Kate Lampo and Will Specht came up with a creative solution—to use decorative LED fairy lights from the nearest store (about 45 minutes away) instead. CSI counselors got to work splicing and twisting wires and melting off wiring insulation in order to make these fairy lights function into disconnected LEDs. After hours of work, we had created about 300 LEDS, which we were able to put to use during the activity. The joy of the students when they managed to put together a working circuit made the twists and turns of the preparation well worth it.

We can’t wait to see what camp has in store for us next year!

– Outreach Team

This past spring, CSI’s Outreach team received the Robert D. Lilley Award for Socially Responsible Engineering at Columbia’s 2024 Leadership and Excellence Awards. This award is given by the Dean of the School of Engineering and Applied Sciences at Columbia to the engineering group that best creates engineering projects in economically or socially disadvantaged areas, student research projects directed towards topics that relate to socially responsible engineering, and campus education efforts that focus on engineering ethics.

We were awarded for our work with our educational space science program that reached over 1,000 students in under-resourced middle schools in the past year. Some of our work includes model rocketry, a balloon-dropping activity, and a paper-airplane lesson. In our model rocket lessons, we teach students about aerodynamics and design considerations when making a rocket, then they build their own rockets with components manufactured by CSI volunteers. We then launch the rockets at their schools to help bring these aerodynamics lessons to life. The balloon-drop activity and paper airplane lessons are interactive activities that are a part of our “auditorium programs,” where we teach students about space and engineering principles such as aerodynamics, astronomy, and structural design.

At the end of the year, we host Spaceposium as our culminating event, where members of all CSI missions are able to present about their year-long projects to fellow peers, members of the Columbia community, and students from our partner middle schools. At our most recent Spaceposium in April 2024, Outreach members gave a coding lesson to students where they learned the very basics of programming. Then, they were able to put what they learned to use by writing code to guide a robotic car through a maze. Other activities included plasma lab tours and poster sessions where middle schoolers got the chance to learn about CSI’s missions. We are so honored to be recognized with this award and look forward to continuing our work in exposing STEM to middle schoolers across the city!

Read more about the award here: https://www.cc-seas.columbia.edu/awards/honorees/2024

– Outreach Team

CSI’s 2024 Micro-g tool, the SEE LION, was an autonomous camera and computer system that utilized image recognition model techniques to identify objects present during an unassisted egress scenario from the Orion capsule (astronauts floating wearing an underarm life preserver, astronaut multi-person life raft, etc). The mechanism was required to be built using off-the-shelf hardware, splash-proof for poolside testing, and operate within an allotted time.

Throughout the development of the SEE LION, a large emphasis was placed on ensuring a smooth and straightforward user experience due to the time-sensitive nature of retrieving astronauts upon returning to Earth. The system, consisting of a tripod-mounted camera, a pelican case containing the necessary computing resources, a laptop with a dedicated user interface for the system, and a secondary monitor, was ideated to minimize the complexity of the tool and allow the operator to quickly set up the SEE LION with simple instructions.

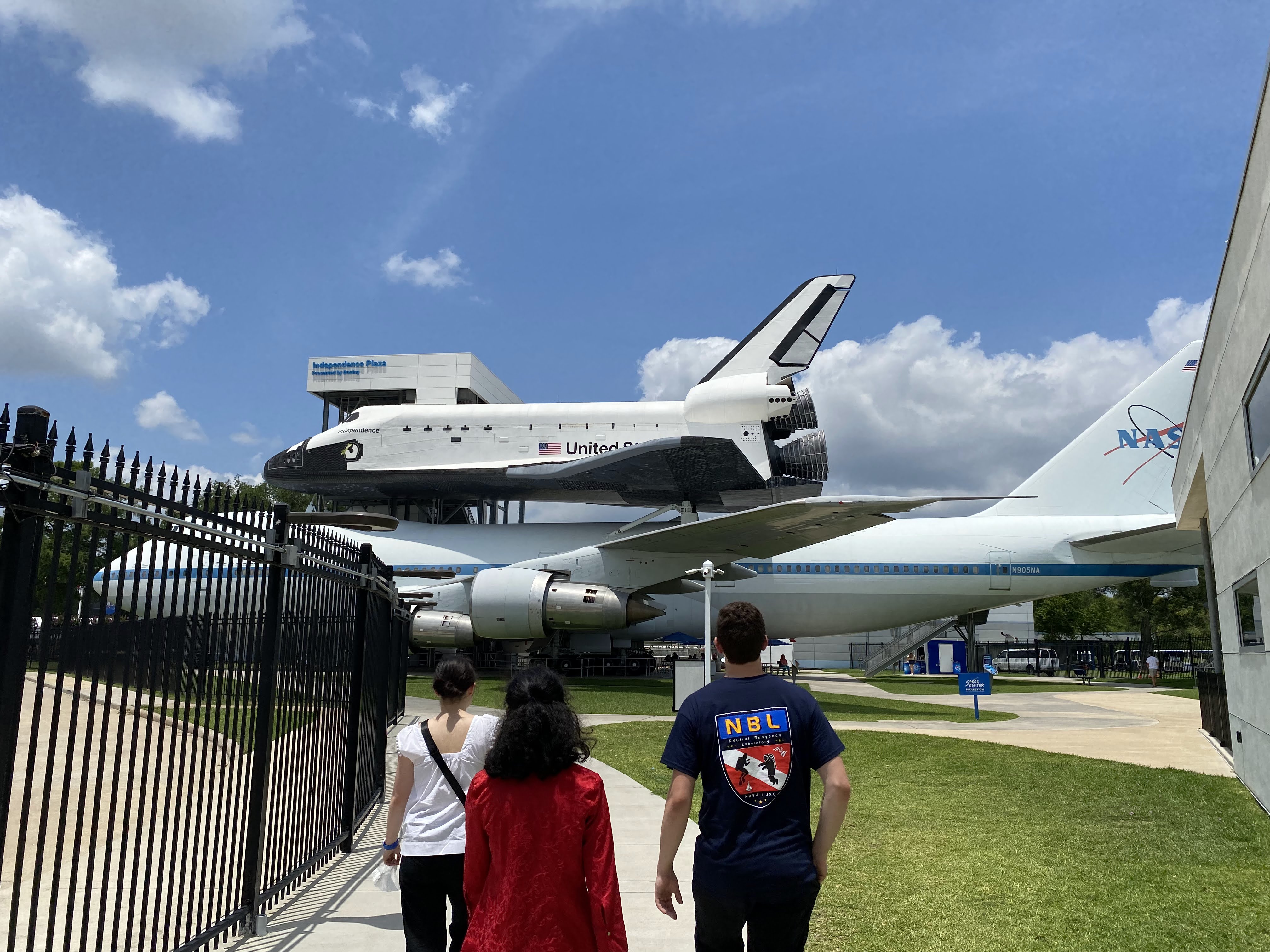

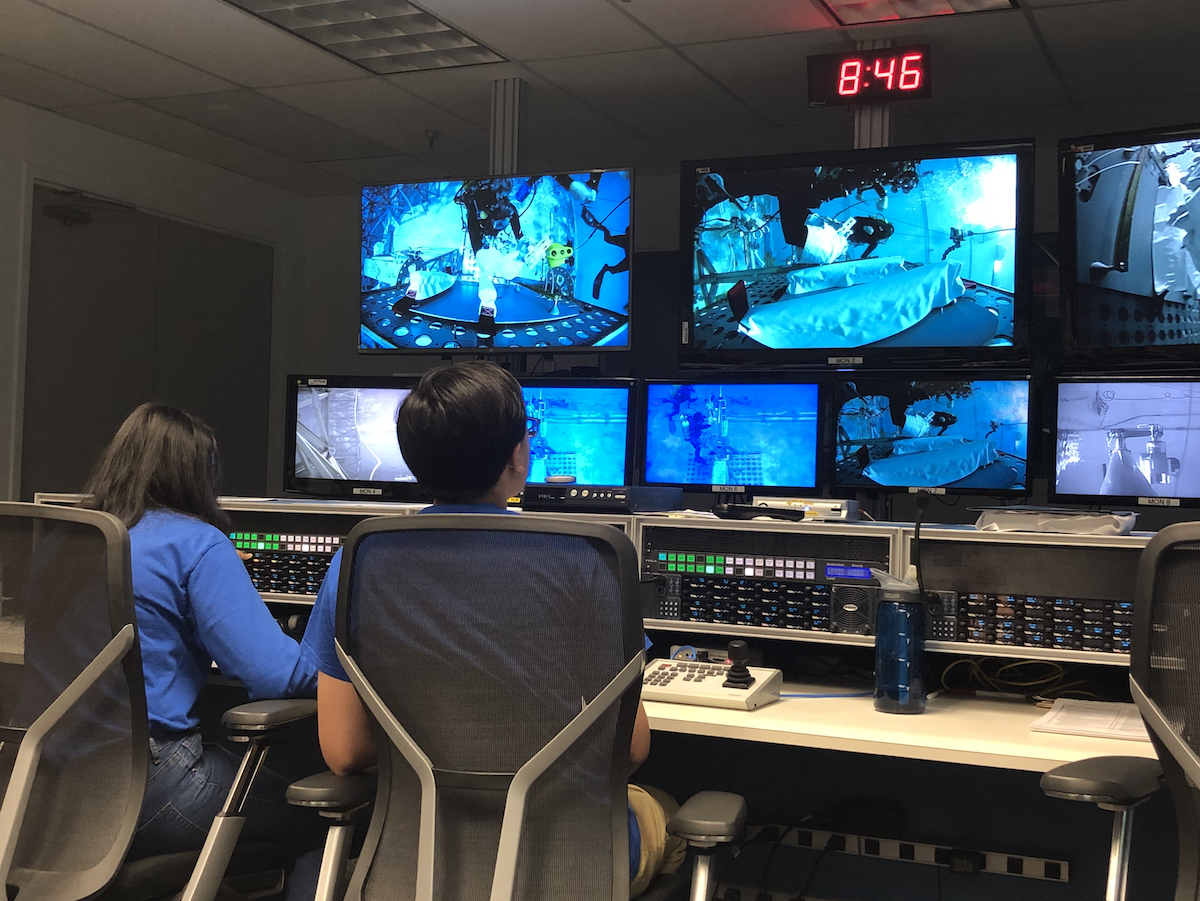

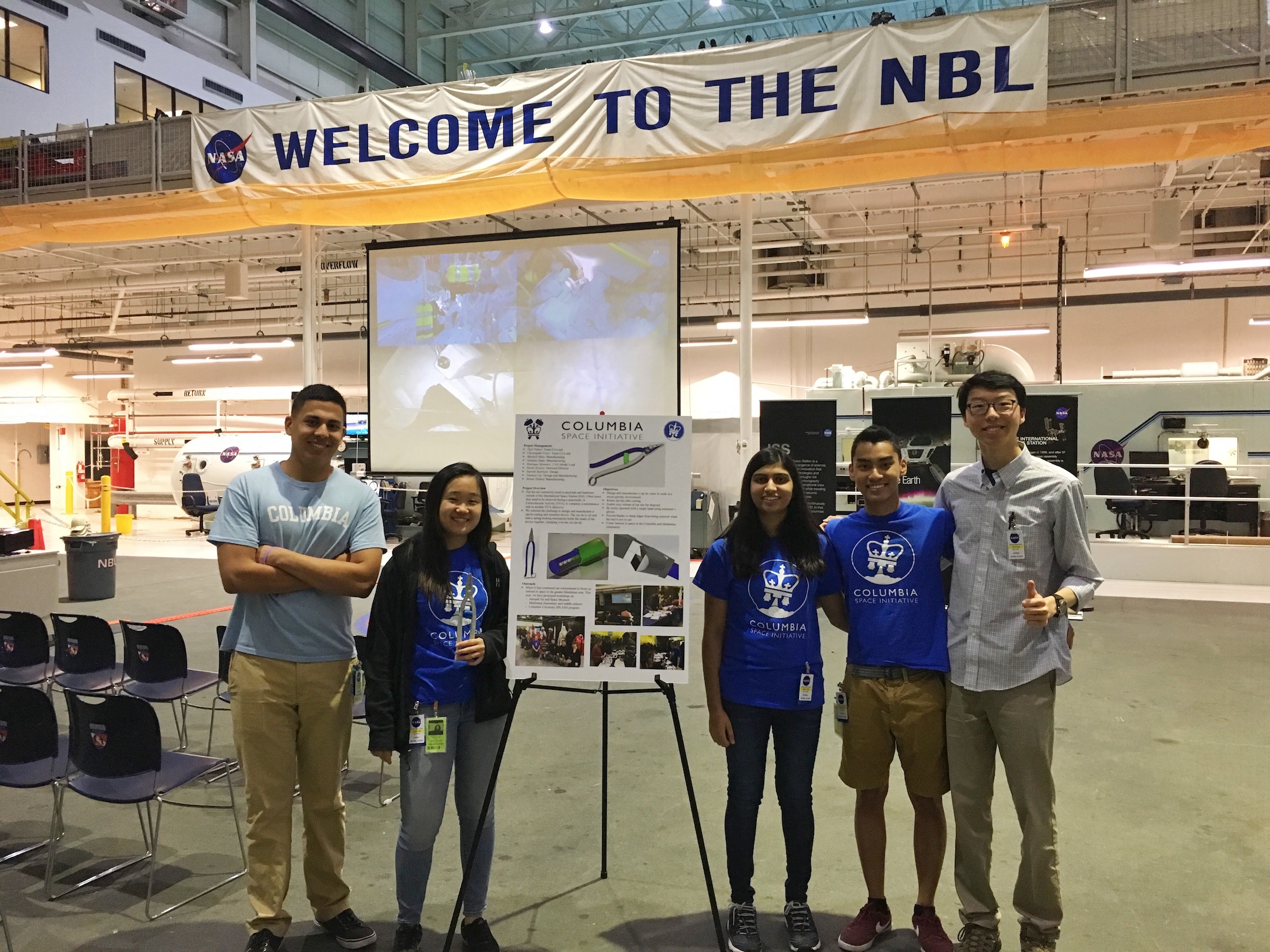

Our year-long project culminated in our team traveling to NASA’s Neutral Buoyancy Laboratory (NBL) in Houston, Texas. At the NBL, we were invited on multiple tours that spanned the buildings housing Artemis Program space shuttles and equipment to old Apollo and Soviet space systems. Additionally, we spent time at Mission Control watching the controllers in real time and working with people on the ISS, which was an exciting experience. As the week progressed, our SEE LION was tested at the Neutral Buoyancy Laboratory pool, undergoing strict procedural checks to maintain the highest levels of safety and accuracy. Through daily testing and troubleshooting, we successfully identified three of the four objects at the NBL with a high confidence of identification. As our session at the NBL started winding down, we connected with the Micro-G team at UT Dallas and bonded over some iconic Texas barbeque. It was a satisfying experience and a wellworth trip for all of us, receiving important feedback from NASA and meeting some amazing individuals. We can’t wait for the next chance to return to NASA with a new team!

– Micro-g Team

This past week, our Rockets mission successfully launched their nitrous-parrafin hybrid rocket named PleaseGoHigher at the inaugural FAR-OUT competition in the Californian Mojave desert.

PleaseGoHigher went FARther OUT, further Up, and Higher than ever, surpassing last year’s PleaseGoUp rocket and winning second place in its launch category and first place in podium presentations. It produced over a half-ton of thrust, accelerated at 16G’s and successfully deployed parachutes to safely land and be recovered. This rocket was entirely student-designed, manufactured, and tested in-house this year, and is CSI and Columbia’s second-ever rocket launch and first-ever successful recovery.

Huge congratulations to the entire team!

– Tycho Bogdanowitsch, Former Co-President & Rockets Co-Lead

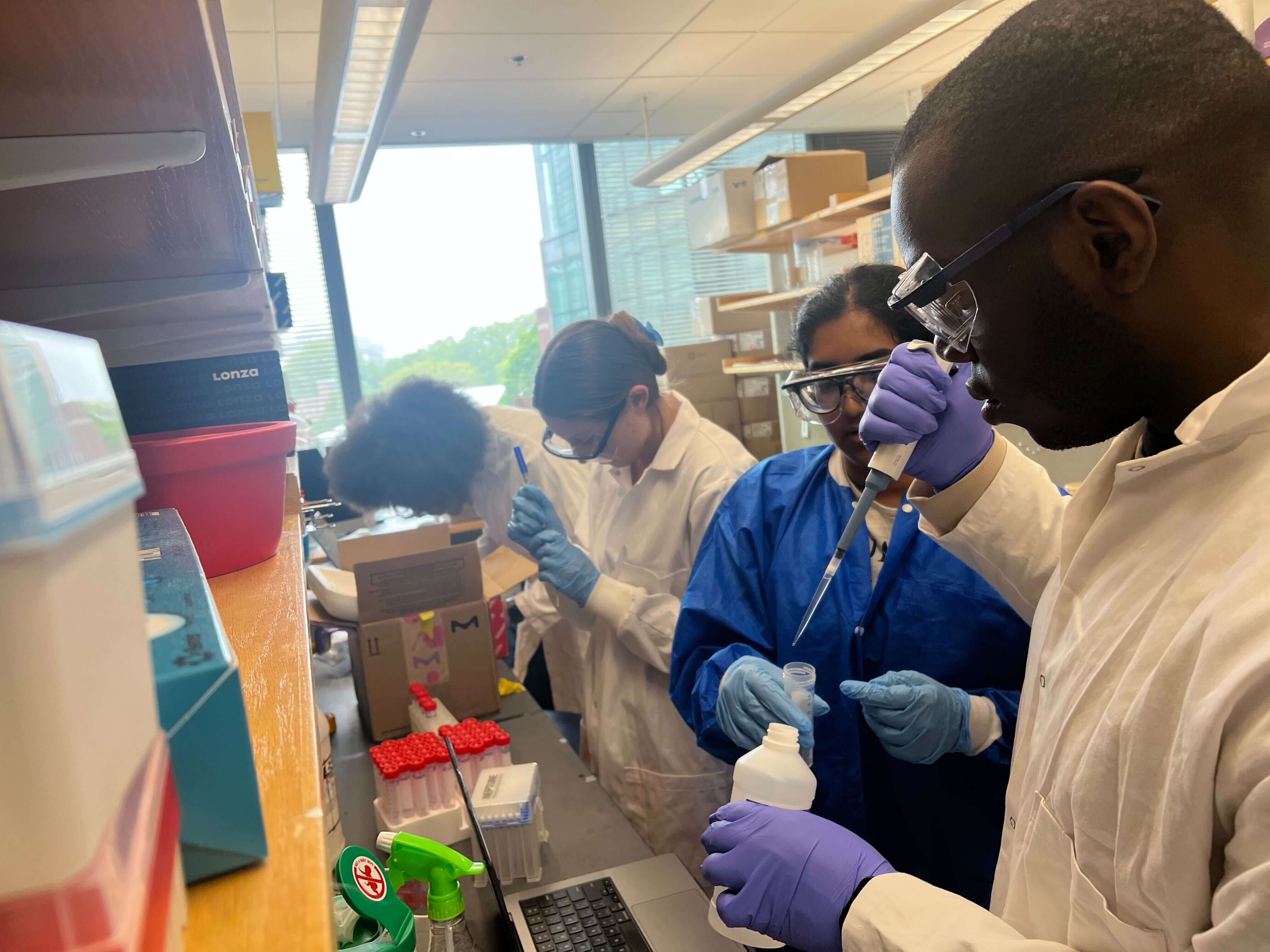

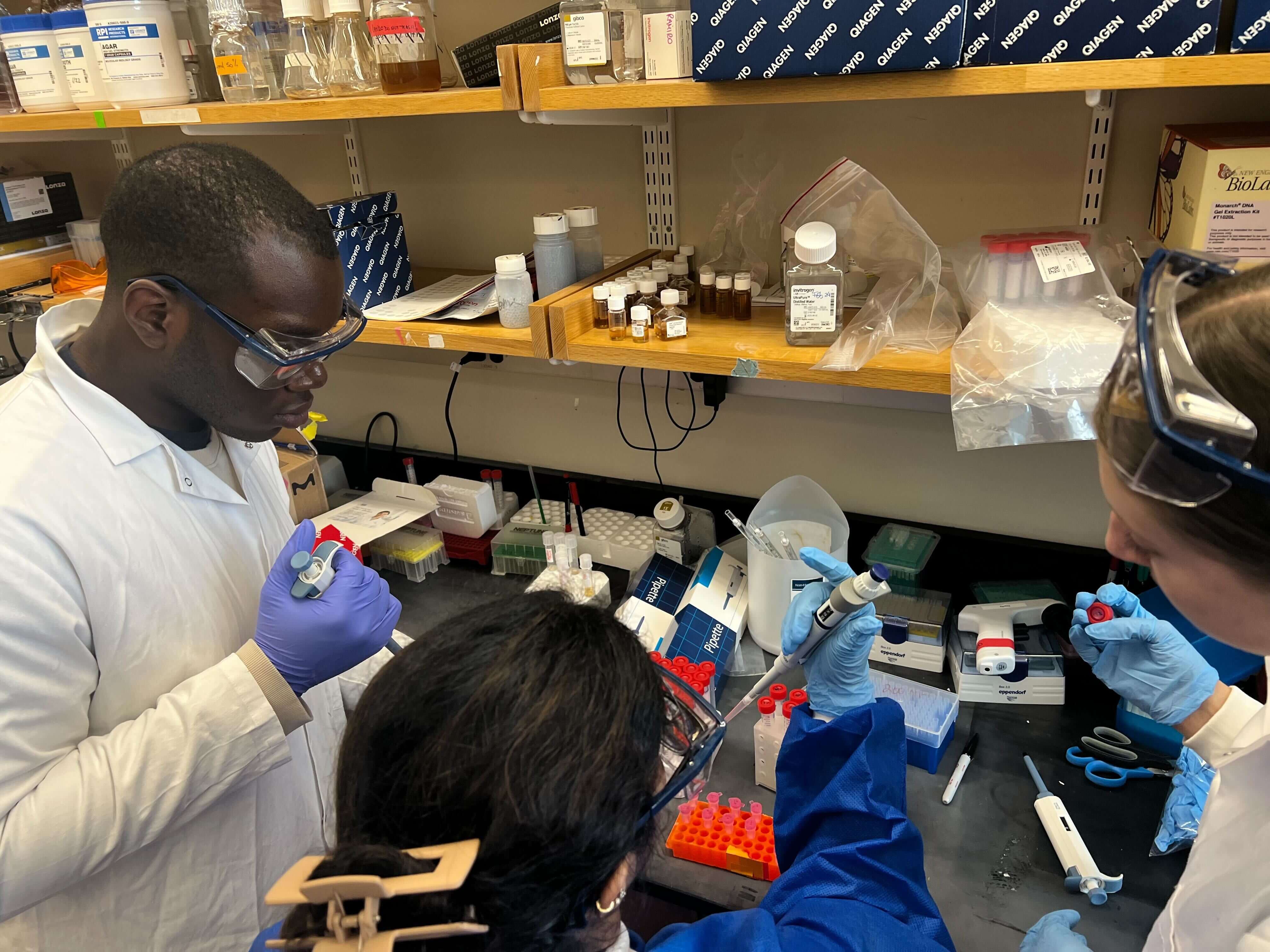

The Astrobiology mission spent the academic year learning about spaceflight and its effects on biological systems–namely, spaceflight-induced anemia and decreased bone density due to long-term exposure to microgravity.

The project aimed to identify changes in the quantity of genetic material pre- and post-exposure to microgravity. To achieve this, the team designed, prototyped, and implemented their own in-flight hardware, which allowed for a timed release of DNA/RNA preservative into HeLa cells for further extraction, isolation, and quantification.

From May 17th to May 24th, the team took their samples to Boston to collaborate with the George Church Lab at Harvard, and to New Hampshire to work with Weill Cornell’s Dr. Christopher E. Mason for an authentic microgravity experience via the Aurelia Institute and their parabolic flight programming.

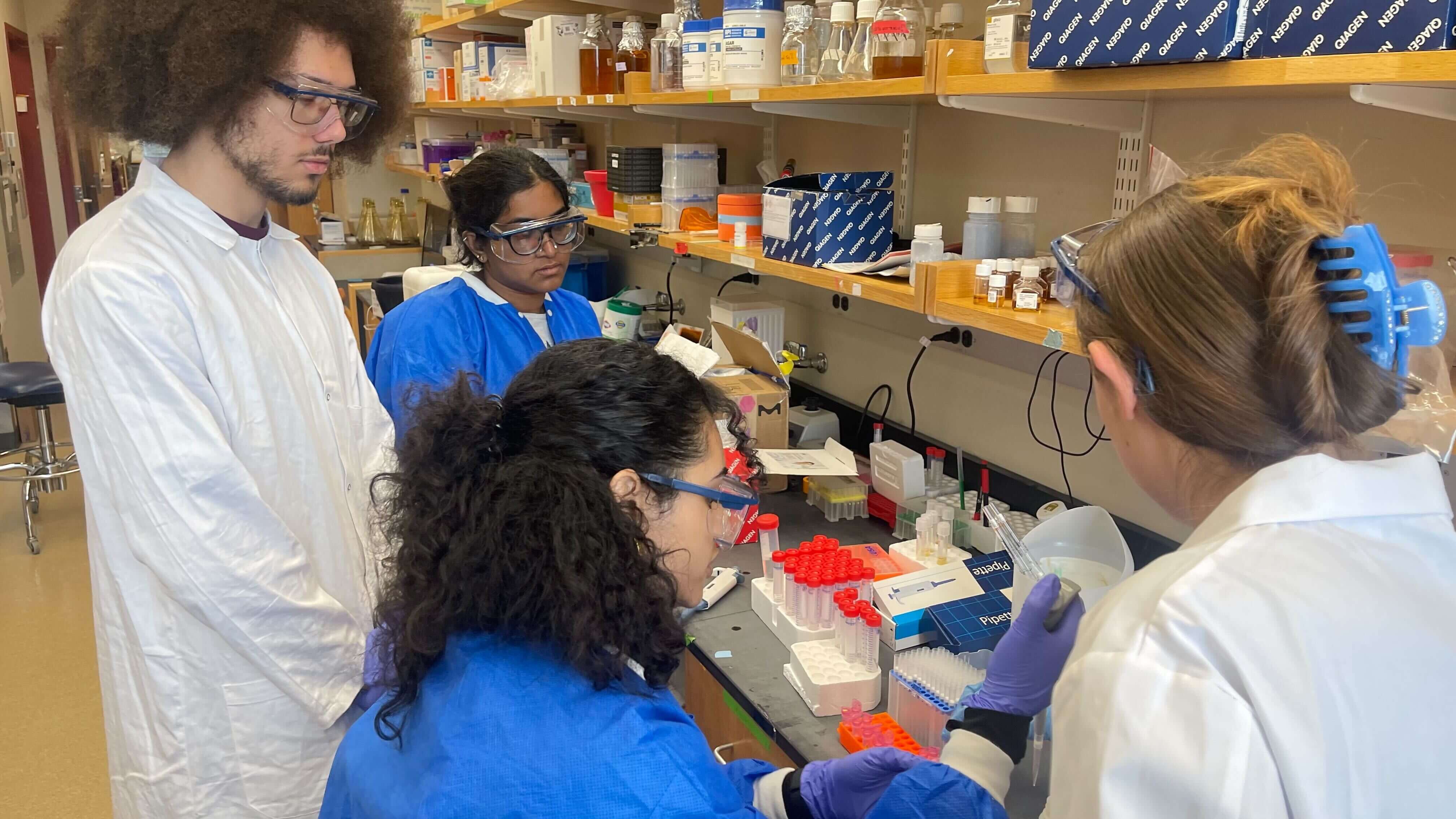

See below for a selection of pictures from their visits.

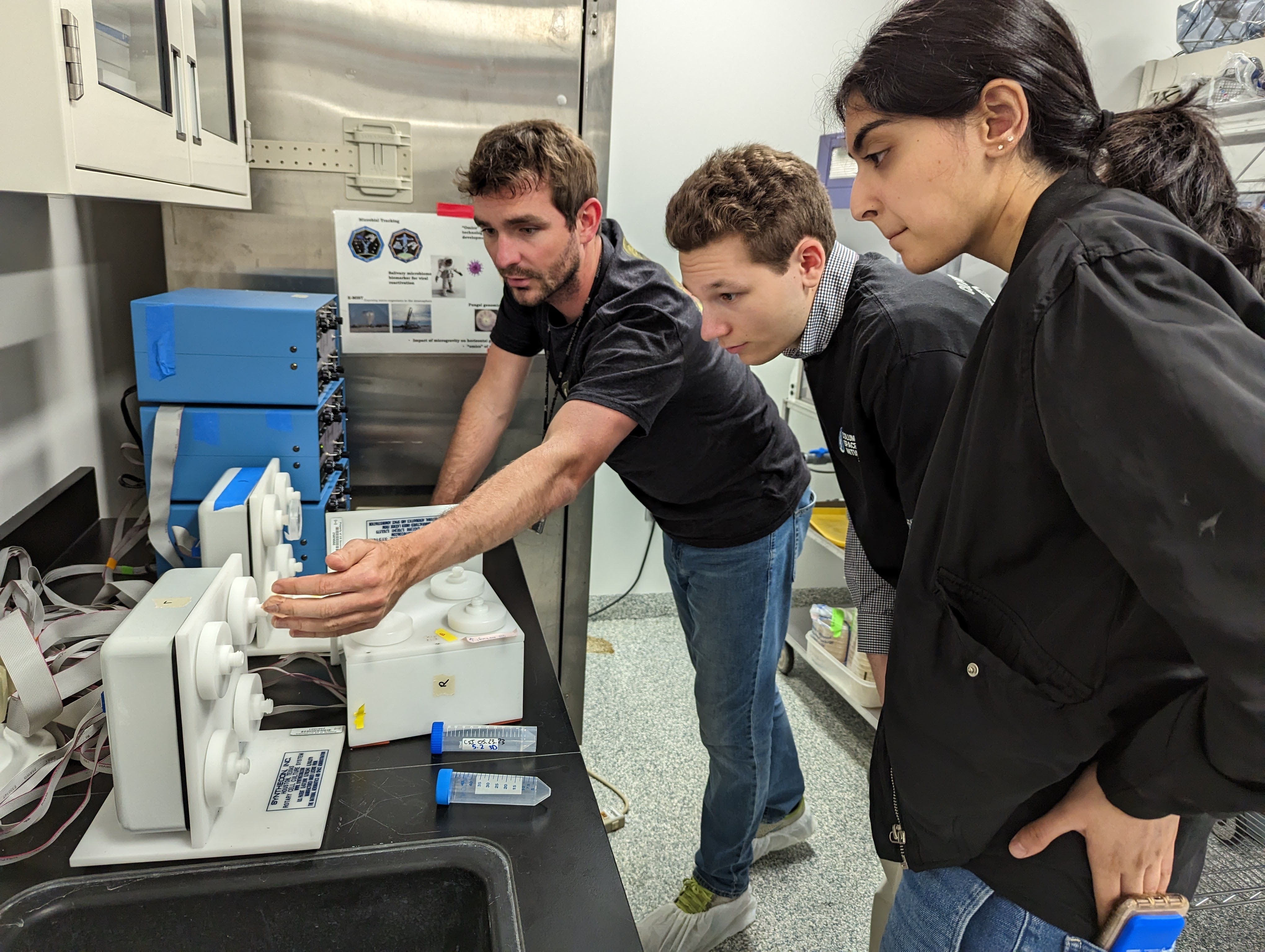

A special look into the Space Microbiology’s visit to NASA’s Jet Propulsion Laboratory (JPL)!

Host Dr. Ceth Parker, and Space Microbiology Co-Leads Miriam Aziz and Theodore Nelson, inspect the rotary cell culture system (RCCS) from Synthecon, one of the 2D ‘simulated microgravity’ clinostats.

From left to right: Dr. Ceth Parker, Theodore Nelson, Miriam Aziz

Image courtesy of Jake Lee

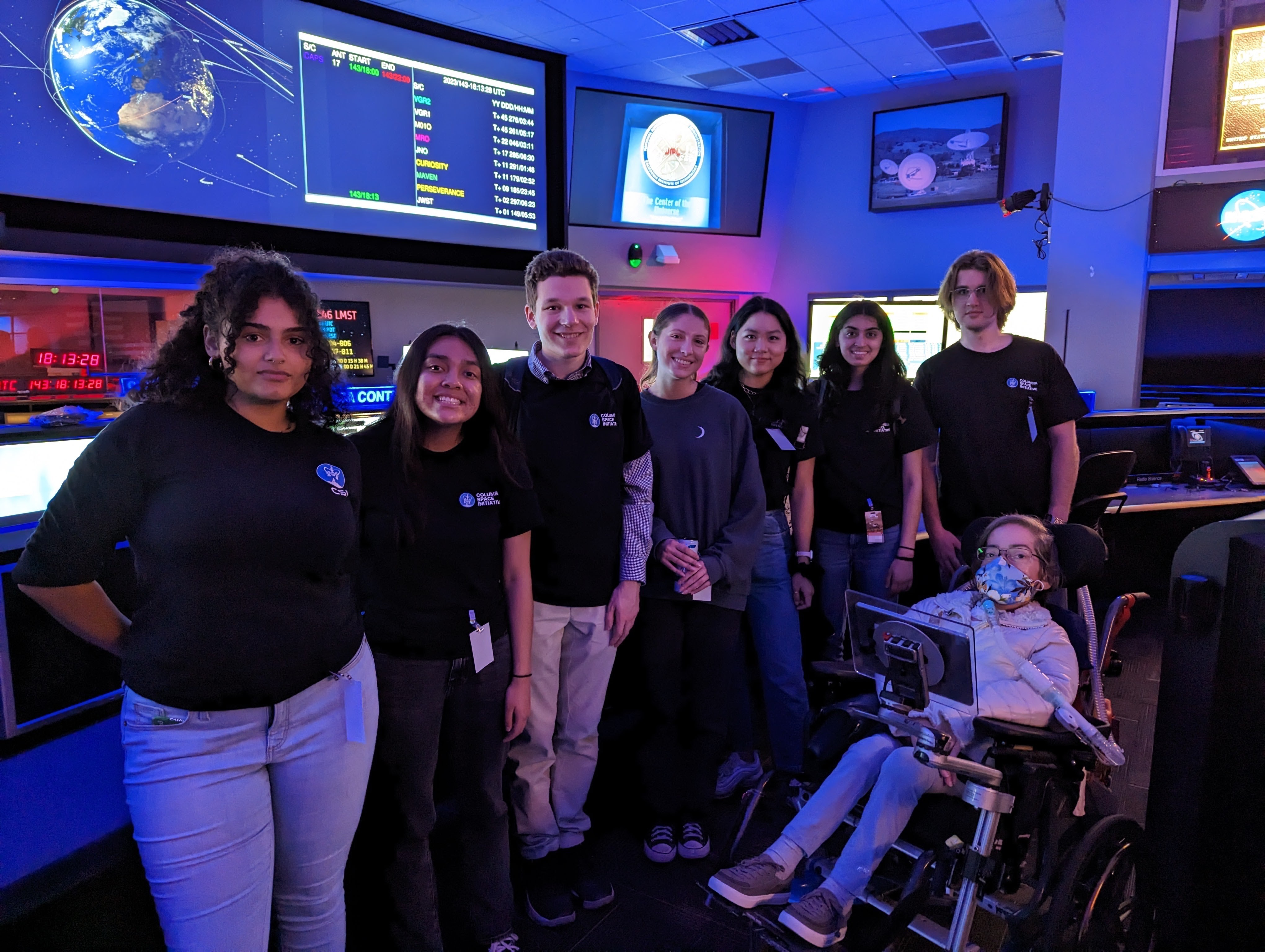

JPL Escort Jake Lee and the Space Microbiology Team pose for a photo in the lobby of the Mission Control Center at NASA JPL.

From left to right: Jake Lee, Miriam Aziz, Theodore Nelson, Michelle Brose, Błażej Raszewski, Chloe Jones, Rashell Ramirez, Somin Lee, Brianna Przywozny

Image courtesy of Jake Lee

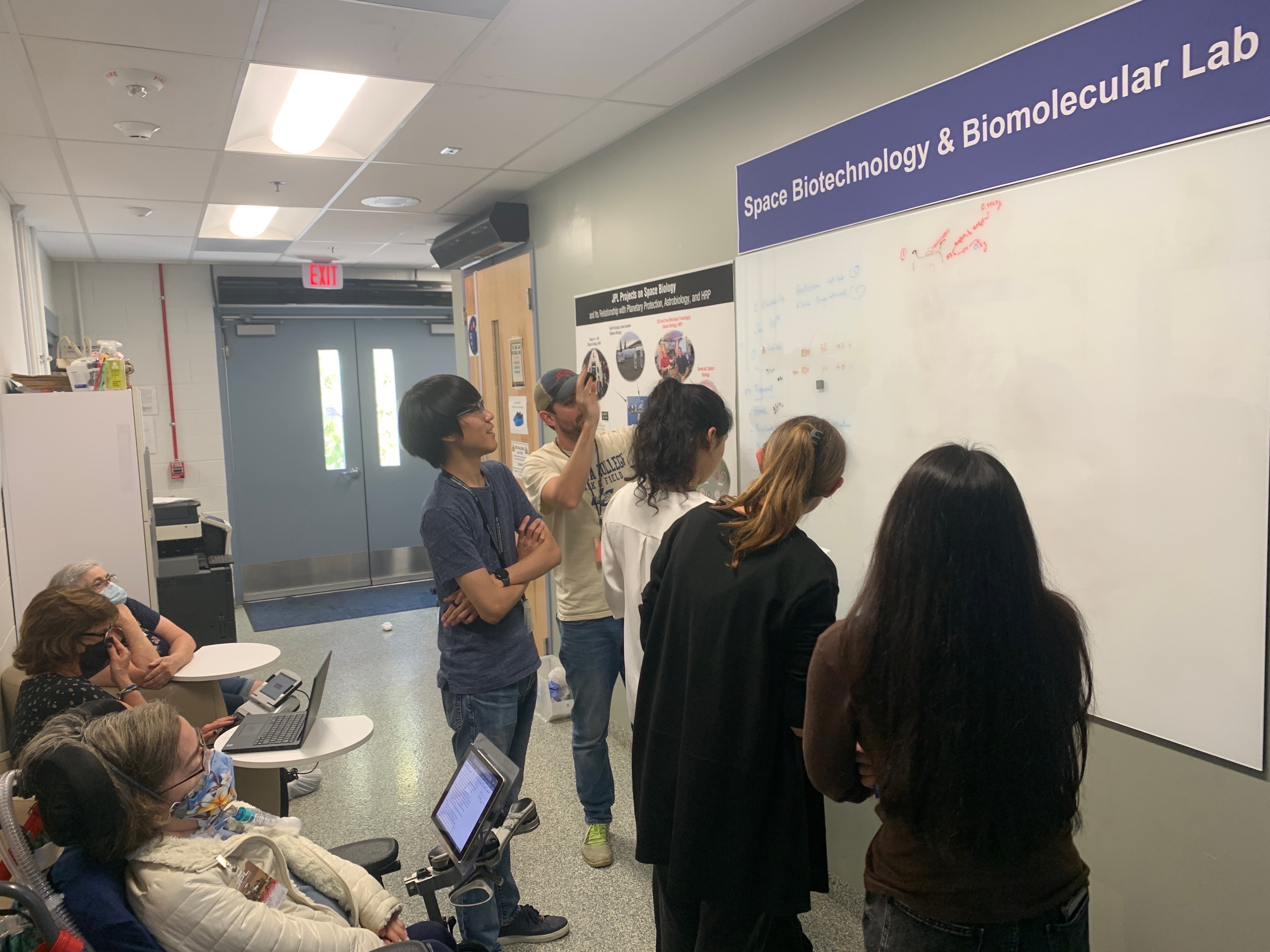

Host Dr. Ceth Parker, and Space Microbiology Team Members Somin Lee, Michelle Brose, Brianna Przywozny, and Rashell Ramirez outline the planned zinc oxide formation experiment on the whiteboard.

From left to right: Michelle Brose, Jake Lee, Dr. Ceth Parker, Somin Lee, Brianna Przywozny, Rashell Ramirez

Image courtesy of Miriam Aziz

The Space Microbiology Team poses in front of a sign that reads ‘Dare Mighty Things!’ a slogan associated with NASA’s rover missions to Mars.

From left to right: Theodore Nelson, Miriam Aziz, Brianna Przywozny, Somin Lee, Michelle Brose, Rashell Ramirez, Błażej Raszewski, Chloe Jones

Image courtesy of Theodore Nelson

The Space Microbiology Team poses in front of the stone JPL sign at the entrance to the campus.

From left to right: Michelle Brose, Theodore Nelson, Miriam Aziz, Somin Lee, Brianna Przywozny, Rashell Ramirez, Chloe Jones

Image courtesy of Theodore Nelson

The Space Microbiology Team poses inside the JPL Mission Control Center.

From left to right: Chloe Jones, Rashell Ramirez, Theodore Nelson, Brianna Przywozny, Somin Lee, Miriam Aziz, Błażej Raszewski, Michelle Brose

Image courtesy of Jake Lee

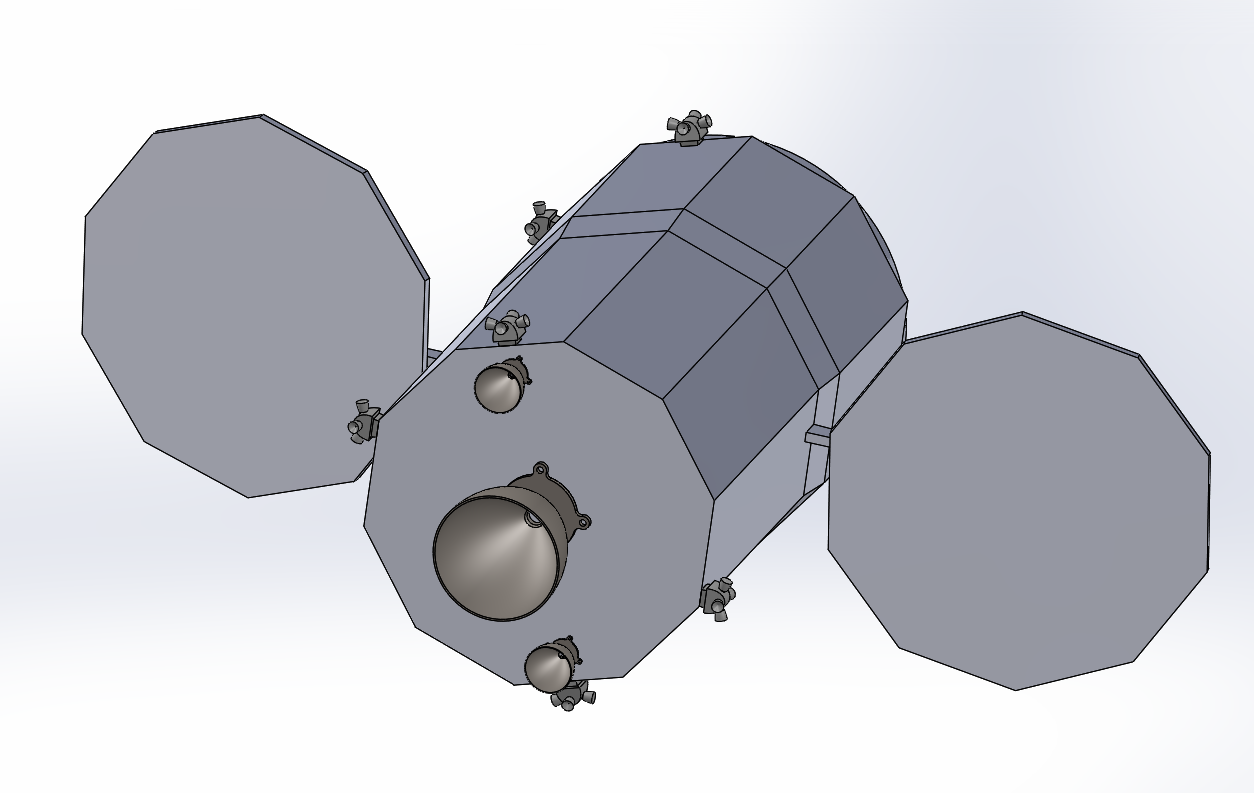

CSI’s 2022 Micro-g tool, LionLatch, was designed as a gripping and anchoring mechanism for use on the lunar surface during NASA’s upcoming Artemis missions. This year’s challenge asked teams to design and manufacture an anchoring mechanism able to provide holding force on a variety of objects with different types of faces. The mechanism was required to work in the dusty, microgravity environment of the lunar surface, and had to be purely mechanical, not utilizing any sort of electronic aid or chemical adhesion.

In designing this year’s tool, the LionLatch team focused on the astronaut experience, endeavoring to create a design that was simple to use and that required minimal effort to actuate. The design, which can be used comfortably from a standing position, is manipulated with one simple pull of a handle. It consists of six identical legs, dubbed “macrospines” for their likeness to traditional microspine technology. Each leg has several joints that can navigate around rocks of varying sizes and textures, as well as a roller to aid in the actuation process. All six are pulled into a gripped position by passive spring forces acting on each joint, meaning there’s no need for astronauts to actively grip their targets. The pads on the end of each macrospine are also coated in gecko gripper material, which leverages biomimicry and Van Der Waals forces to provide non-sticky friction during the gripping process.

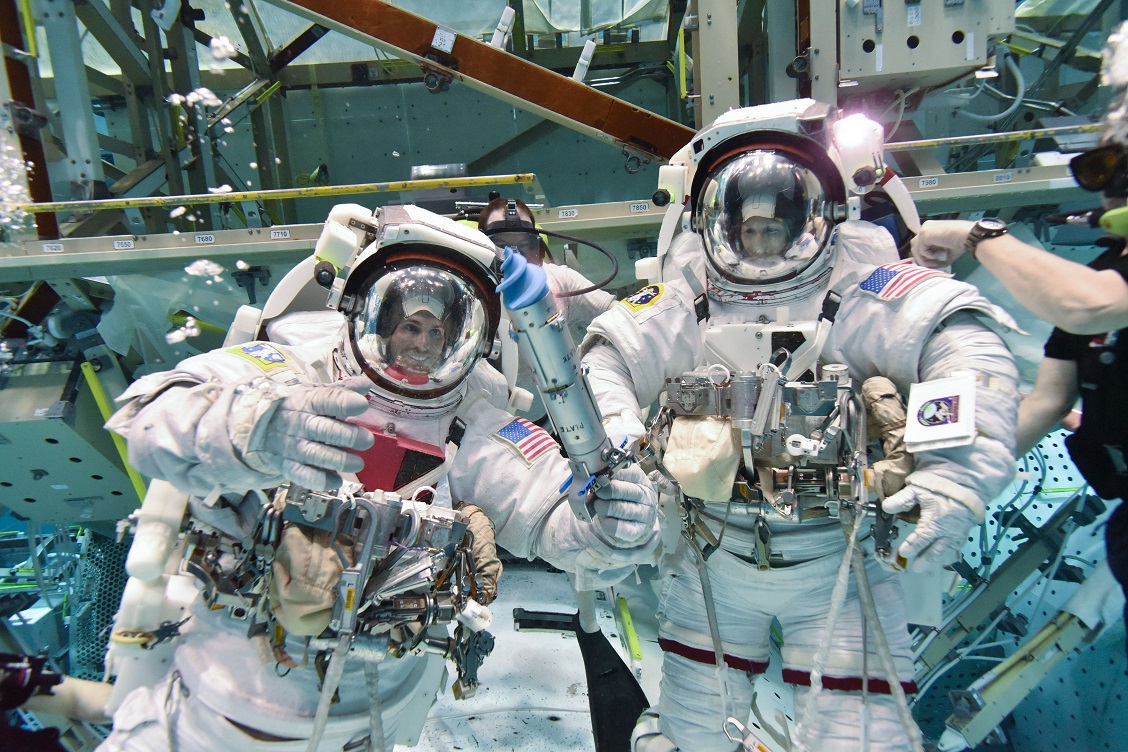

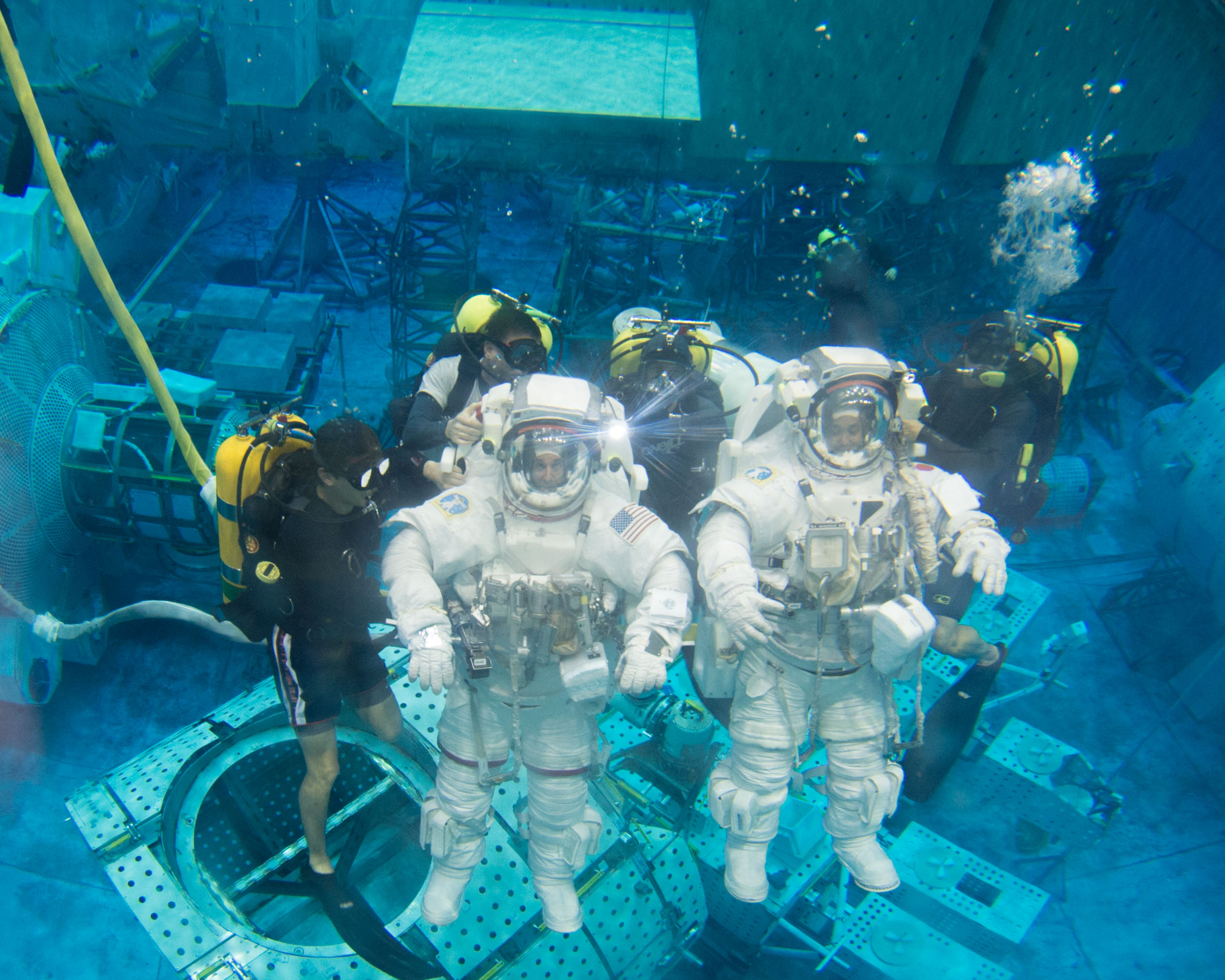

After a year’s worth of design, development, and manufacturing, the LionLatch team traveled to NASA’s Neutral Buoyancy Laboratory (NBL) in Houston, TX in June 2022. Over the course of testing week, we toured NBL facilities, gave presentations on our design, and worked alongside a diver to test our design in the NBL pool’s simulated microgravity. Our time in Houston was a rewarding learning experience, and we’re thankful for the opportunity to learn from seasoned engineers and to see many crucial aspects of NASA firsthand! It was a satisfying end to a successful year, and we’re grateful for the feedback we received, conversations we were a part of, and individuals we met. Until next time!

– Team LionLatch

NASA’s Micro-g NExT Challenge is an annual competition for undergraduate students to design, build, and test tools that address current space exploration challenges faced by astronauts in microgravity environments. This year, the challenges all focused on aspects of the Artemis program—NASA’s upcoming lunar mission—to address issues such as sample collection and dust tolerance in a lunar environment.

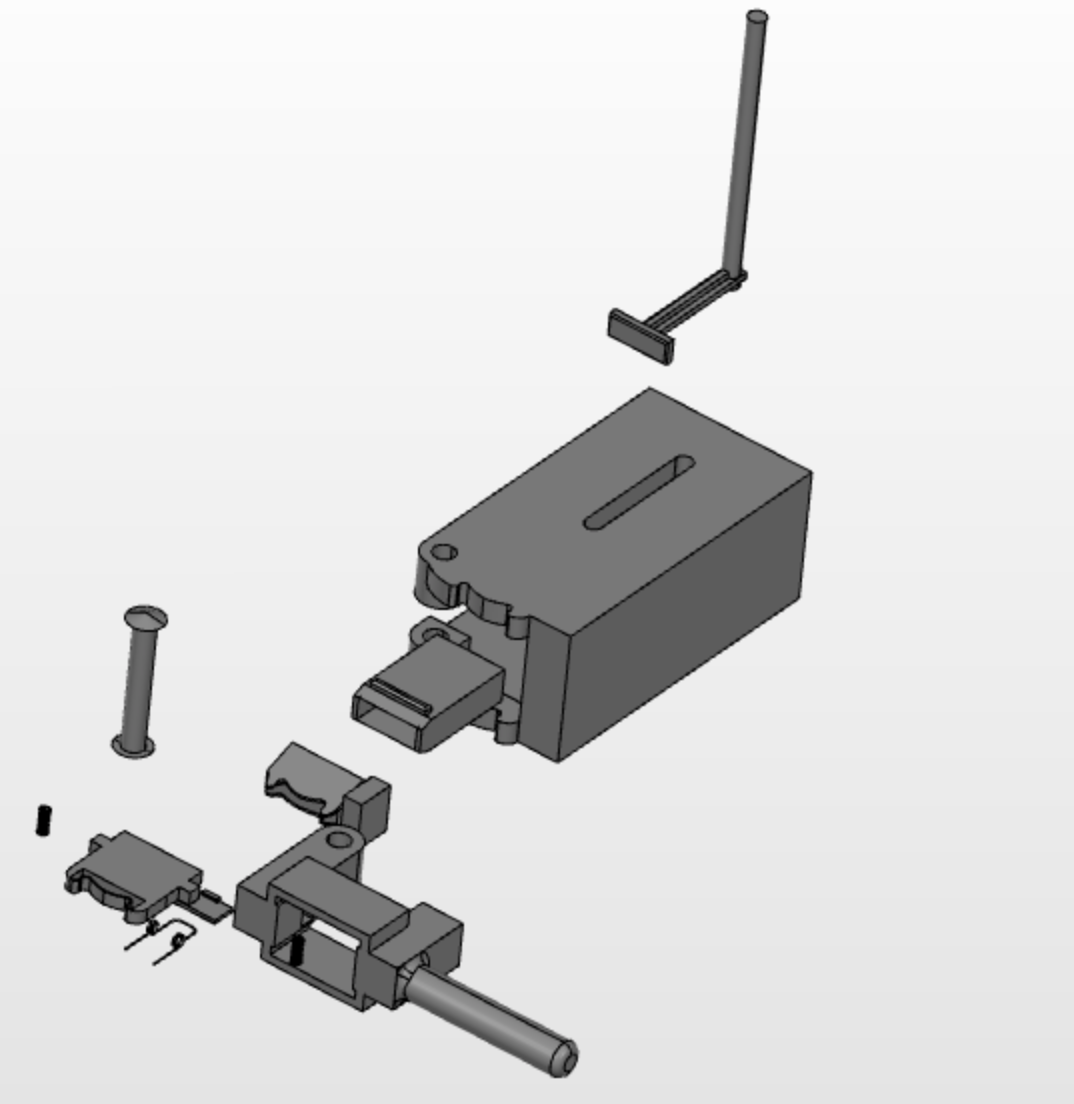

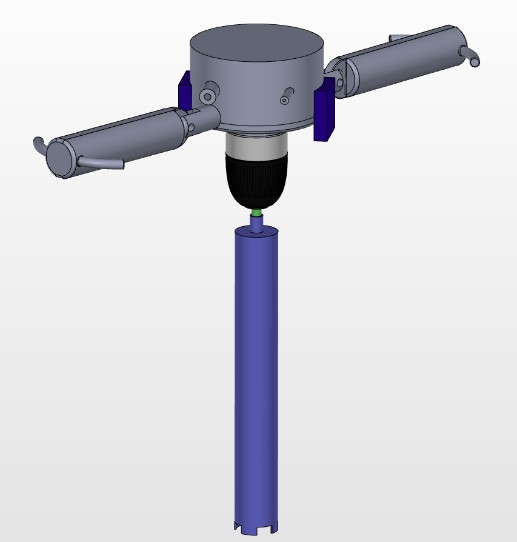

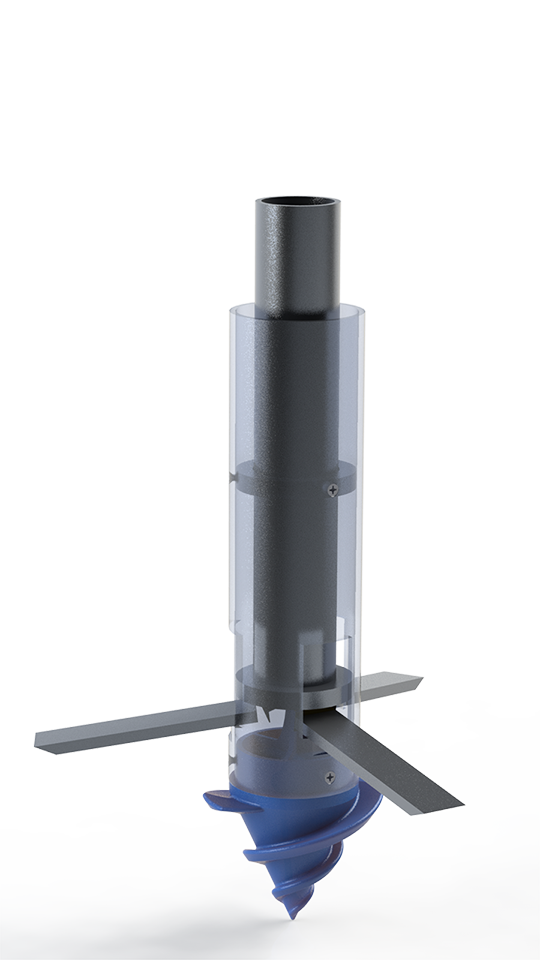

CSI’s 2020 Micro-g NExT team, Lion Core, participated in the Lunar Sample Coring Device project proposed by NASA’s Jet Propulsion Laboratory, designing a drill bit to collect core samples of lunar regolith. We began the design process in early September 2019, focusing our attention on designing a drill bit that could interface with NASA’s underwater diving drill and capture a pristine sample of either concrete or ice as per the challenge guidelines. Because our final tool is dive-tested at the Neutral Buoyancy Laboratory in Houston, TX each year, we worked to additionally ensure our coring drill bit could operate underwater and be easily used in a simulated lunar (1/6th gravity) environment.

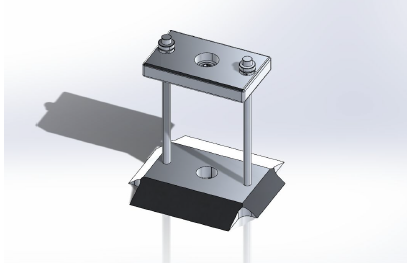

After two months of work on our design, we created the Handheld Assistive Removal Device to Capture Observable Regolith Elements (or HARDCORE for short.) HARDCORE consists of (1) a coring drill bit that can capture core samples of 0.5” in diameter and 3” deep and (2) a stabilization jig that allows for easier core extraction in the lunar gravity environment. We submitted a proposal to NASA outlining the design and intended operation at the end of October 2019 and were selected as finalists in early December to manufacture our device and test it in the NBL.

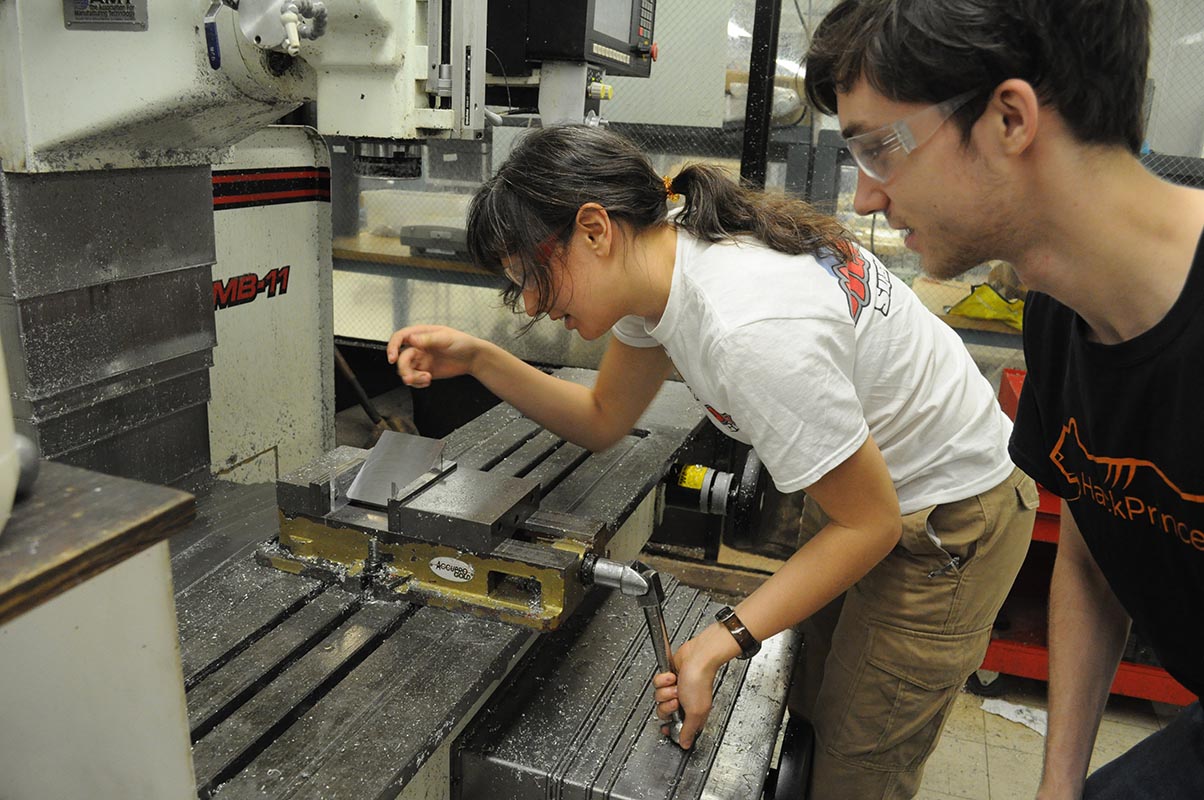

Since submitting our proposal and hearing of our finalist status in the competition, our team has been hard at work updating our design, manufacturing our device, and testing prototypes in the Columbia Makerspace and Mechanical Engineering Shop. Our initial coring bit testing yielded promising results, with the drill bit able to capture a core sample from ice. We have since updated our design to assist in capturing a more pristine sample and streamlined our stabilization jig design to be lighter and more stable.

We have been continuing to make steady progress with our design updates and prototype manufacturing, despite being dispersed around the continent due to COVID-19. Our team now meets virtually and will continue our manufacturing process over the summer with the goal of sending our final tool to the NBL for remote testing in early September!

– Micro-g Team

Our payload launched today on Blue Origin’s “New Shepard” rocket. This was the first payload Columbia University (and CSI) have sent into outer space! Big thank you to all the team members who have worked hard on this mission during the last 1.5 years, and to the Mechanical Engineering Department for funding it.

-Nathalie Hager, Zero-G Research Division Lead

Spread across countries and continents, we are continuing the development of our payload during this summer. The BME subteam is finalizing the experiment setup and will be conducting tests in a laboratory on campus soon. The CS subteam is working on the on-board software, while the Mech-E and the EE subteams are both working on the manufacturing of the payload locker. We are also working on the payload documentation required by NanoRacks/Blue Origin. Space missions know no summer breaks!

-Nathalie Hager, Zero-G Research Division Lead

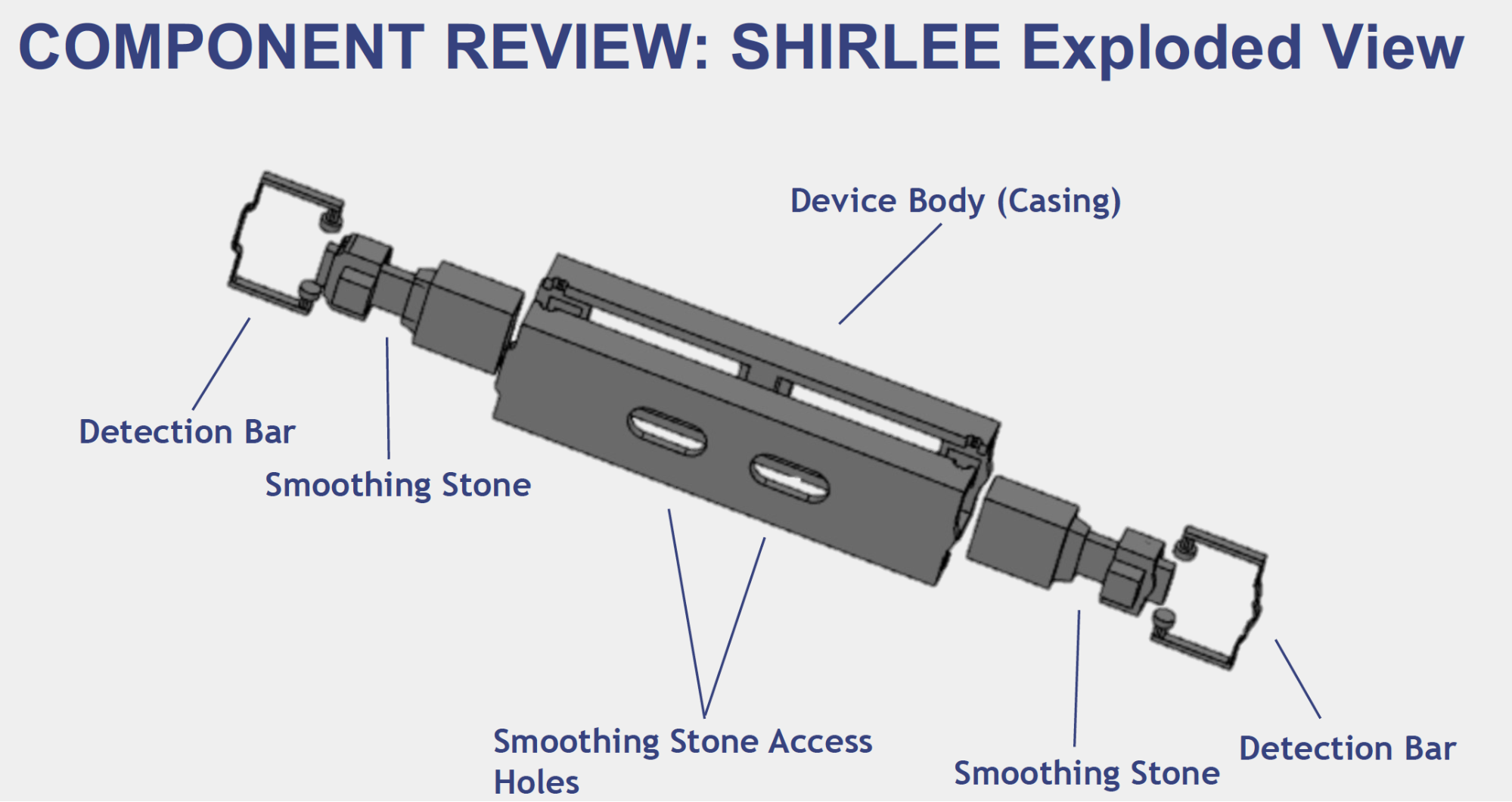

Micro-g NExT is an annual NASA design challenge to design and manufacture a device that functions in a microgravity environment and addresses a problem that astronauts face on either the International Space Station (ISS) or during spacewalks. One such problem is sharp edges on the handrails along the outside of the ISS created by collisions with Micrometeoroids and Orbital Debris. Astronauts rely on these handrails to move around during Extravehicular Activities (EVAs) and sharp edges pose a significant hazard to astronaut gloves. This year’s Micro-g NExT challenge asked us to design a sharp-edge detection and removal device to eliminate the risk of sharp edges on the handrails. This two part device would be required to first detect the specific location of the sharp edge along the handrail and then remove or cover the edge without introducing new safety hazards.

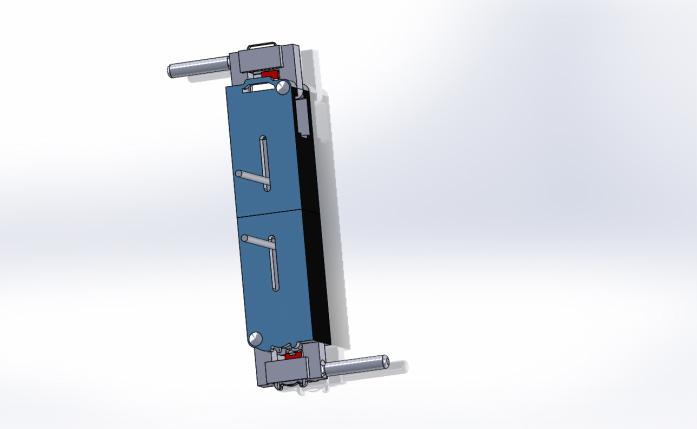

Our device, SHIRLEE (Sharp-Edge Handheld Identifier & Remover in Low-Gravity Extravehicular Environments), shown below, addresses both the detection and removal components of the challenge. The two detection bars protruding from SHIRLEE are shaped to fit the two different curvatures of the handrail faces. When run along a handrail, the detection bar catches on sharp edges and rotates outward which alerts the astronaut of the encountered sharp edge. Beneath each detection bar is a skate stone, which can be accessed once a bar has rotated outward. Skate stones are small blocks of ceramic steel used to reshape and smooth down nicks and sharp edges on the blades of ice skates. SHIRLEE uses these stones in the same way; after detecting a sharp edge, the skate stone can be rubbed against the sharp edge, smoothing down and removing the hazard.

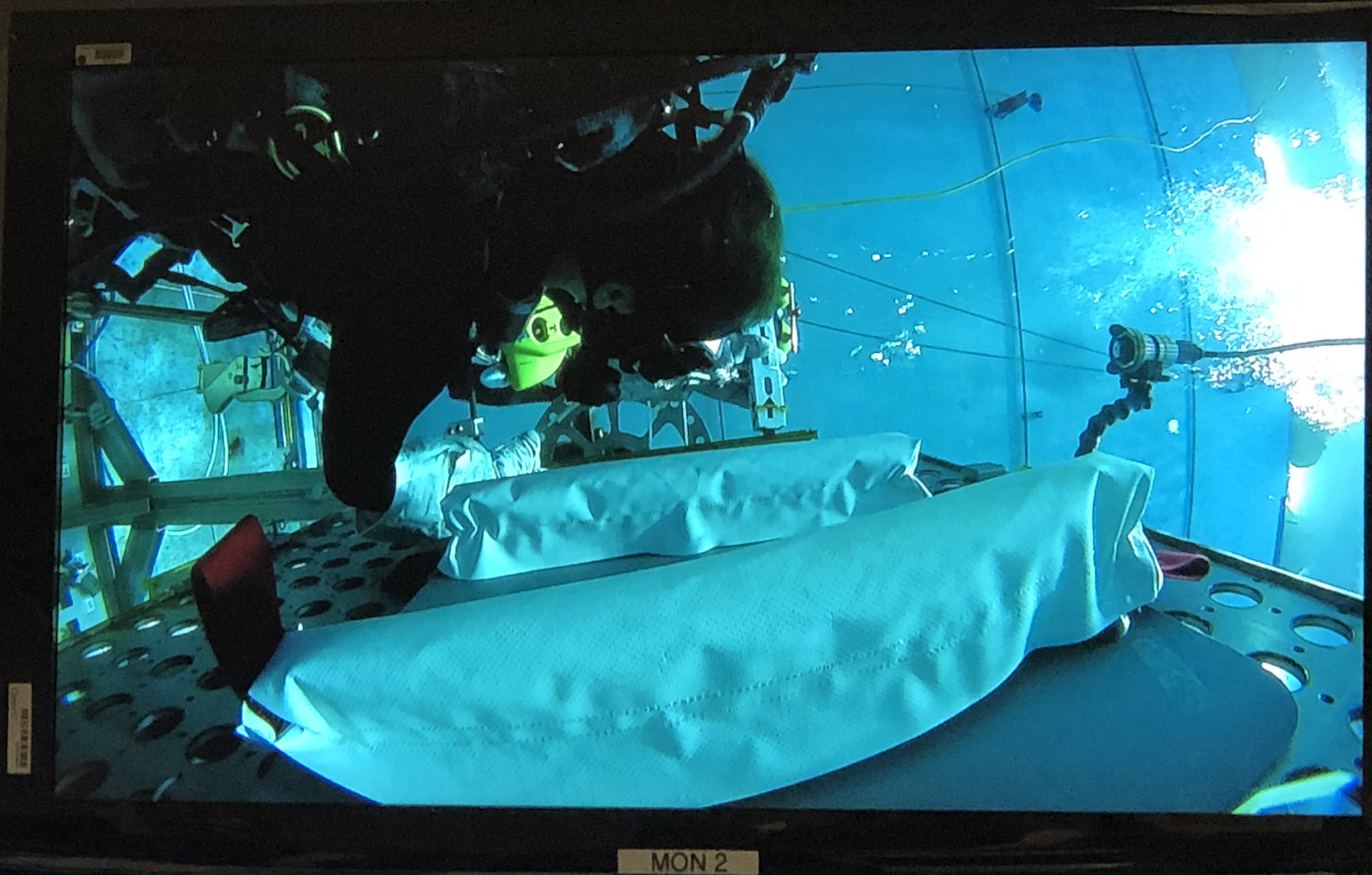

After being selected for the challenge and spending the year designing and manufacturing SHIRLEE, we traveled to the Johnson Space Center Neutral Buoyancy Laboratory (NBL) in Houston, Texas to test the device during our designated Test Week. The NBL is a training facility for astronauts that features a 6.2 million gallon pool. Underwater, it is possible to simulate a microgravity environment and learning to navigate this environment is an essential part of astronaut training. In addition, the pool contains a replica of the ISS, which astronauts use to train and prepare for spacewalks. Functionality in a microgravity environment is not only crucial for astronauts, but is also an essential requirement for the tools astronauts take with them. The purpose of our test week was for an NBL diver to test SHIRLEE underwater to see how it would perform in a microgravity environment.

Our first day at the NBL was focused on safety. To ensure diver and astronaut safety, every material or device to enter the pool must be thoroughly reviewed. After meeting the other teams, the divers, and the safety review board, we presented our Test Readiness Review, providing an overview of SHIRLEE and how we addressed each potential safety concern in the design of our device. SHIRLEE was approved for testing the next morning and we finalized our operations plan (the step by step directions we read to the diver during testing).

Our test took place the next morning. First, we had a poolside check-in with our diver, Emily, to make sure she understood the basics of the device and how it should be handled. Once in the control room, team member Swati read the operations plan to Emily over a two-way radio while watching the test in real time on several monitors. Our test was a success! SHIRLEE detected and removed several sharp edges on a test handrail and the diver gave us very positive feedback, describing SHIRLEE as very effective and ergonomically easy to use.

We spent the remainder of the trip compiling testing feedback, touring the Johnson Space Center (JSC), learning about other teams’ designs, and presenting our results. From seeing mission control to learning about suit and tool design from JSC engineers, we had the opportunity to see many crucial aspects of NASA firsthand. We also made some time for team bonding, celebrating a successful year with some movies, bowling, and karaoke. Both the yearlong mission and its culmination during test week were incredible and we can’t wait to see what’s in store for next year’s Micro-g team!

– Team Lion Edge

Since the start of our mission in Summer 2018, we’ve been working hard on the development of our payload throughout the past academic year. Our four subteams - BME, Mech-E, EE and CS - have developed the entire experiment design together from scratch. In addition, we have secured funding for the development of our payload and for the launch fees for a spot on New Shepard. We also have successfully secured a spot on the P9 flight of Blue Origin’s rocket and are looking forward to the launch!

-Nathalie Hager, Zero-G Research Division Lead

When astronauts step into space, they enter an environment in which sharp objects are an immediate threat. With highly pressured suits, the slightest wear on a glove can be dangerous, compromising the entire space suit’s integrity. As a result, astronauts at the international space station must take extreme precaution when exiting their ships for space walks. They rely on handrails which help them maneuver outside the ISS. These handrails, which make direct contact with each astronaut’s glove, are susceptible to developing sharp edges, due to the impact of Micrometeoroids and Orbital Debris.

To remedy this problem, NASA has proposed a design challenge. The objective of this challenge is to design a method for both detecting sharp edges and removing sharp edges from an Extravehicular Activities handrail.

When it came to actually sketching a prototype our team recognized the following constraints: The device must be easy to use. Since the astronaut will be wearing clunky gloves, we could not design anything that required intricate handling by the user. Because the device will be tested at the Neutral Buoyancy Laboratory, it must work underwater. This means we have to be very cautious about the materials we chose. The device must work on all three faces of the handrail, each of which is shaped differently. As a result we designed parts that are fitted to the varying concavity of each of the faces.

Our device utilizes detection bars that slide along the face of the handrail and fit the face’s curvature. When a sharp edge appears on the handrail, the bottom section of the bar is thin enough that it will catch on any sharp protrusions it comes in contact with. When caught, the entire detection bar will be pushed in against two compression springs. As the device continues to move, the latch located on the detection bar will release its grip on a trigger flap, enabling this flap to pop up. This signals the presence of a sharp edge.

When a sharp edge is detected, a red signal appears. This tells the astronaut to lift the device from the railing and move the detection device to the side, which will reveal nozzles that contain fast drying covering paste. As the astronaut depresses the plunger, covering paste is squeezed onto the bar. The astronaut can then drag the device over the area covered to help smooth the covering paste across the face.

A current design challenge for our team is to design a better way for astronauts to grip the device. Currently the body of the device is cubic and requires astronauts to grip around the body’s edges. We plan to create a covering grip, or shape the body differently, so that is better suited to the shape of the astronauts glove and relies less on grip strength.

As of now, we are moving from the design phase into the prototype phase. We are currently pending acceptance for NASA’s competition at the Johnson Space Center this spring! Wish us luck :)

– Micro-g Team

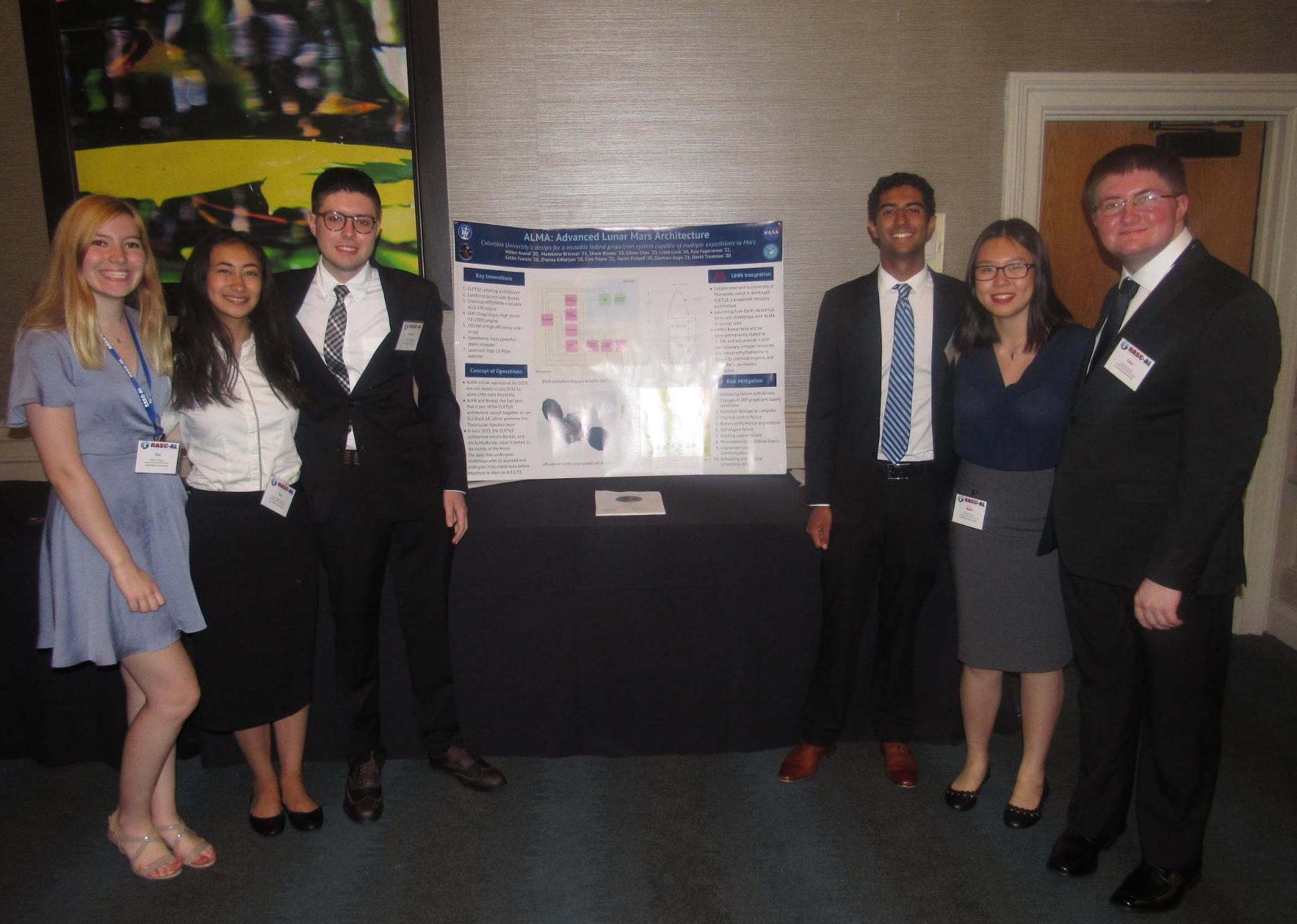

CSI’s RASC-AL mission has a long history–well, as long a history as possible in a three year-old club–of success. This was Columbia’s third year participating in RASC-AL, a NASA-sponsored aerospace engineering competition, and its third year advancing to the finals in Cocoa Beach, Florida. However, CSI’s legacy by no means guaranteed our success. We had to work hard to move from sitting in CSI’s interest meeting in September to standing in front of NASA, presenting our reusable hybrid-propulsion stage design. Our team has come far this year, and looking back at the past nine months, it’s been an incredible journey.

We were tasked with developing a reusable, refuelable in-space stage that utilized both an electric and a chemical engine, and could transport a payload from cis-lunar space to Mars orbit and back. The development of our Advanced Lunar-Mars Architecture, or ALMA, began with delegating subsystems to each team member. Everyone specialized in something, from thermal control to trajectory to communications. We spent first semester researching systems, conducting trade studies, and determining what technologies and techniques would benefit our design. We also took on the extra challenge of working with a group from the University of Minnesota, who provided ALMA’s refuelling architecture. Collaborating remotely with another school wasn’t easy, but the partnership was beneficial on both sides. Not only did our designs profit–working together saved money and added efficiency–but we learned a lot about effective communication and collaboration. The Columbia-UMN partnership was ultimately the only successful one in the competition, as we were the sole partnership that advanced to the finals. But before we could get there, we still had to perfect our own design.

As the spring semester arrived and our abstract, mid-project review, and final paper deadlines approached, we combined our individual research into a streamlined paper and presentation. With each successful submission, we developed our sections, adding more specifics and analysis as well as new considerations such as a budget and risk-mitigation. Finally, in April, we received the good news: we were going to NASA! After a year of preparation, it was thrilling to stand in front of the judges and present our design. Though there were some hiccups (notably, an outdated version of our presentation being displayed, necessitating some improvisation), the presentation went well. ALMA was largely well-received by the judges, but we were also given feedback to make our future designs even stronger. Next year, we plan to perform more in-depth analysis, go into more detail about our development and testing processes, and reevaluate our risk mitigation process.

We were the second of fourteen teams to present, so the pressure was off for the rest of the week. We spent lots of time on the beach, hanging out with each other and getting to know the other teams. The trip culminated in a tour of NASA’s Kennedy Space Center, where we saw the Space Station Processing Facility, Swampworks, and the Saturn V center. The combination of doing cool space stuff and hanging out in Florida created one amazing week. The technical experience and the opportunities provided were absolutely invaluable, especially for a group made up of freshmen and sophomores, but arguably just as incredible was the RASC-AL group itself. I’ve never been part of any project with such a tight-knit team. Thanks to game nights, volleyball matches, and one memorably disastrous baking attempt, we all became friends early in the year and only got closer as the months progressed. The only thing better than going to Florida to talk to NASA was doing so with five of my good friends.

Back in September, many of us joined RASC-AL with no idea where to begin. It was sometimes overwhelming to realize how much I had to learn. But at the end of the day, every research dead-end, long day in Mudd, and logistical challenge was worth it. Reflection on our success is especially significant considering the academic composition of our group. We come from all four undergraduate schools and have majors ranging from mechanical engineering to English. It was inspiring to see people from such different academic backgrounds come together to create something. Of course, there’s always room for improvement. Next year, we’ll reflect on the judges’ feedback and our conversations with other schools as we take on another RASC-AL challenge, and our team leads are writing a post-mortem to determine what can be done better next time. All in all, participating in RASC-AL was absolutely one of the highlights of my year, and I can’t wait to see where we go from here.

– Cleo Payne

The obvious attraction of the Micro-G NExT project is certainly the test week at Johnson Space Center in Houston, Texas. This was what initially drew me to the project in September 2017, but what most people don’t initially look at is the year-long process as a whole. From picking a design challenge to drafting our proposal to eventually testing at the Neutral Buoyancy Lab (NBL), it was an invaluable experience that taught our whole team the value of hard work and collaboration.

Up until we were selected to go to Johnson Space Center in December, the whole process felt very surreal. It still hadn’t hit for many of us that we were actually doing important work that would be considered seriously by NASA. However, when the decision came in, the nature of the whole process changed. Rather than design, we had to focus now on creation. A lot of us were freshmen, which meant we had to learn many different aspects of machining very quickly. The learning curve was steep, but with frequent meetings and countless hours in the MechE shop, we were able to get everything down.

The crux of our device, the spring-lock mechanism, was what really set our initial designs apart from the final product. Cutting zipties was one challenge but being able to retain and dispose of them properly, thereby not allowing them to become more space junk, was something else entirely. Part of this solution was the rubber lining along the bottom clamp of the head of the device, but the other was the spring-lock mechanism. This would lock the device into place once the clamps were closed, keeping the cut ziptie between the two head clamps, and could only be opened again by pressing a lever on the bottom of the mechanism. Other than the machining of the other parts, getting this to work was a huge focus of our project going into the second semester.

Our actual testing experience at the NBL was absolutely incredible. Being able to go past some of the more tourist-oriented parts of Johnson Space Center to really get into the meat of what happens there was a privilege. Even before the actual testing of the device, we were able to meet with several divers, researchers, and other NASA staff. They gave good feedback on the design of our device before and after testing and offered help and guidance along every step of the way. We had a Test Readiness Review (TRR) the first day we were there, during which we talked about how to operate the device and any safety hazards we could find. All of the NASA staff gave very constructive feedback and helped us make the modifications necessary to have a successful test the next day.

Micro-G NExT was an amazing experience, and one that we will all remember. There is a certain part of one’s engineering education that simply can’t be replicated in a classroom and being able to have that, while also doing valuable work for NASA, was an absolute privilege. For next year, I would like to see the Micro-G NExT team continue to pursue an invite to the NBL, and to allow more buffer time for machining issues. A big problem we faced was not allocating enough time for problem we’d run into during manufacturing, and this ended up making things kind of tight in the end. Being a part of this project was amazing, and I look forward to seeing what next year’s team will accomplish!

– David Alvarez

This year, CSI’s RASC-AL team is competing in the Reusable Hybrid Propulsion Stage challenge, and are developing the Advanced Lunar-Mars Architecture (ALMA). The challenge requires in-space hybrid propulsion (chemical and solar electric) that is refuelable in cis-lunar orbit and capable of transporting 50 metric tons to a 5-sol Mars orbit. We are collaborating with a team from the University of Minnesota, who is developing a system to supply ALMA with propellants, rendezvousing in lunar orbit.

* indicates Team Lead

After submitting an abstract of our design, ALMA was selected by NASA to move on to the next stage of competition!

We are developing our Mid-Project Review deliverable for submission on April 1st, and will be presenting our work at a poster session at CU in Space on 3/23 in the Lerner Satow Room from 3-6pm.

– Millen Anand

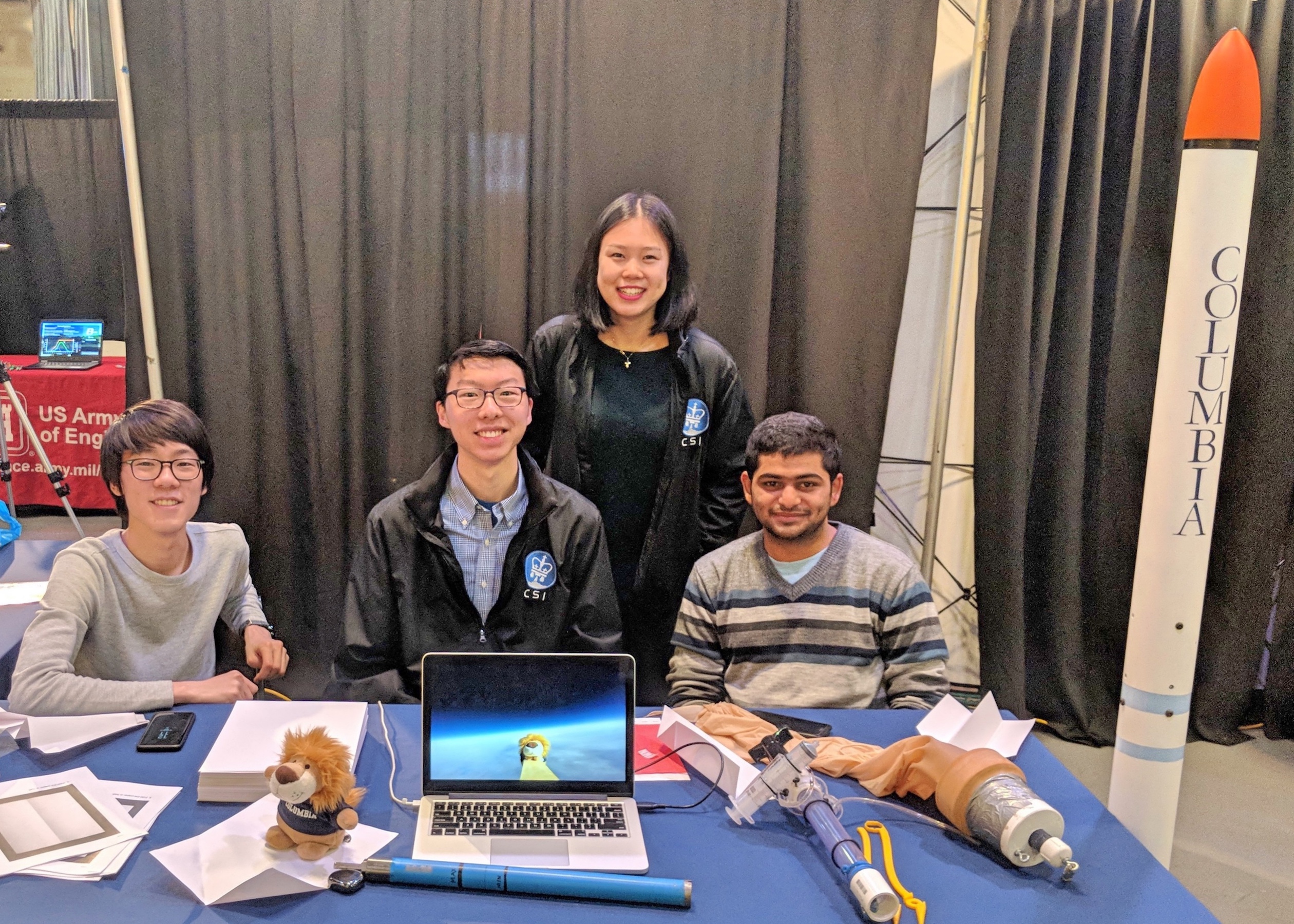

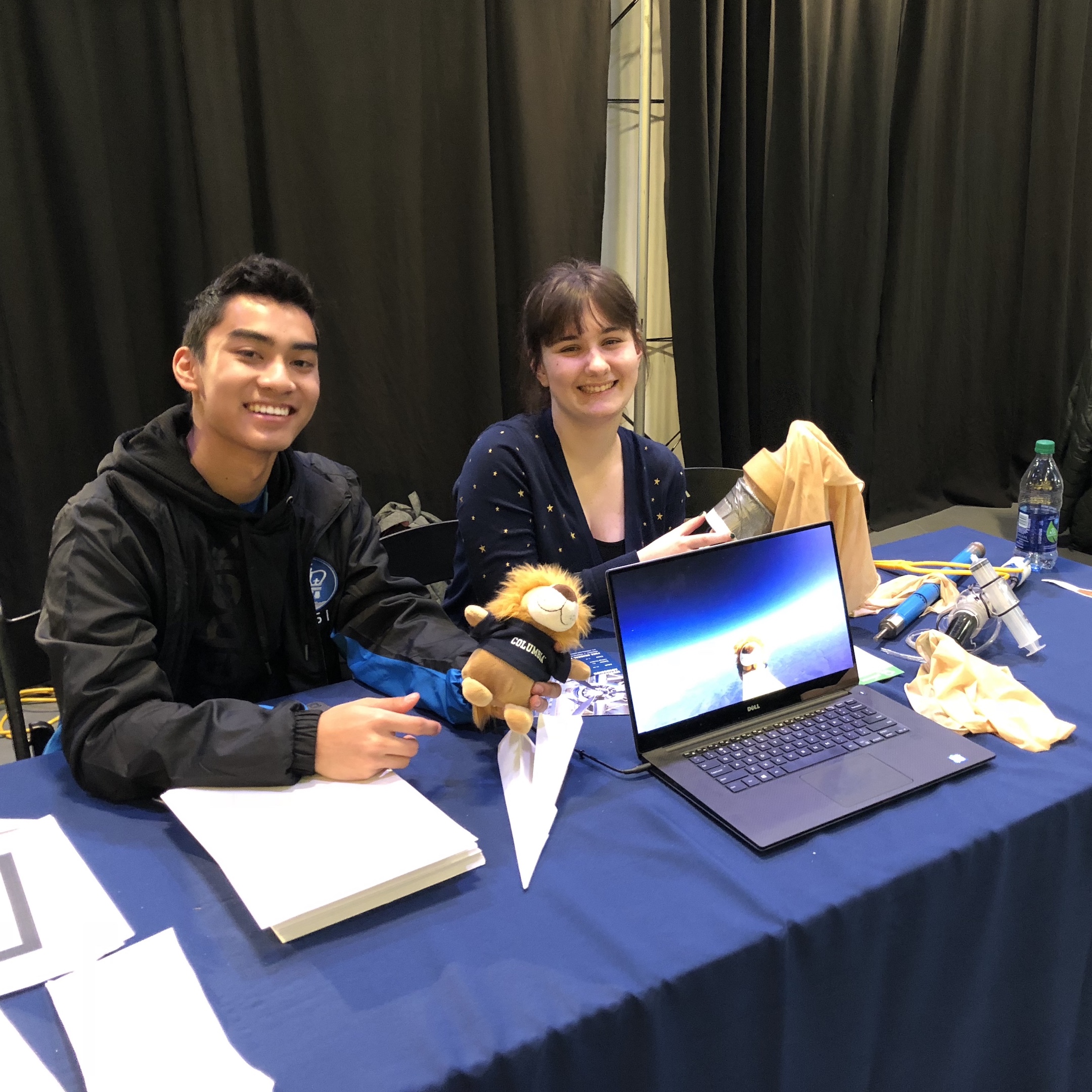

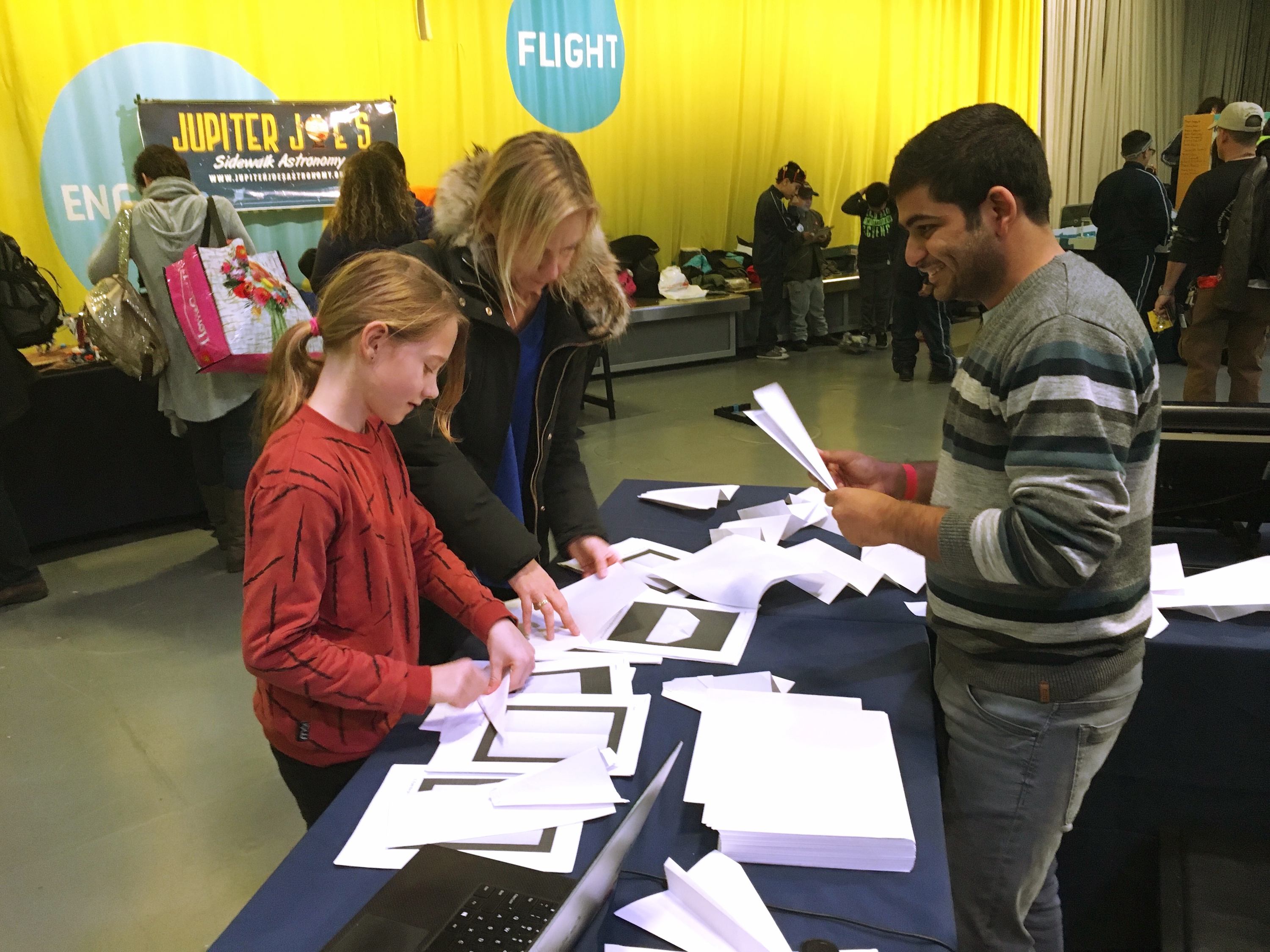

Columbia Space Initiative tabled at Intrepid Sea, Air & Space Museum Kid’s Week to get New York City’s kids interested in engineering and space exploration.

We presented current and previous projects from the Micro-G mission, a model rocket from the rockets mission, and Roaree with a video of his trip to space on a high altitude balloon.

All of the kids that stopped by our table were really interested in our missions and many said they wanted to be future astronauts and engineers. Some of them were as young as five years old, but already had previous knowledge of rockets and current developments in the aerospace industry. We invited the kids make paper airplanes using various designs to demonstrate aerodynamic concepts like lift, drag and thrust.

Ultimately, presenting the work that CSI was a great experience because we got to share our work with curious young minds and we hopefully inspired some of them to pursue space exploration in the future!

– Chris Fryer, Micro-G

The Micro-G teams for 2016 and 2017 did amazing work and we hope to follow un their footsteps!

We’re extremely excited to introduce this year’s Micro-G team!

Zip ties are commonly used on payloads and hardware outside of the International Space Station (ISS). Often times they need to be removed during a spacewalk, or Extravehicular Activity (EVA), to complete a maintenance task or another EVA objective. These zip ties could be anywhere on the payload, including smaller spaces that are hard to reach. Since this occurs in microgravity, the zip tie needs to be captured once removed to keep it from floating away and potentially causing damage to the ISS or another piece of hardware.

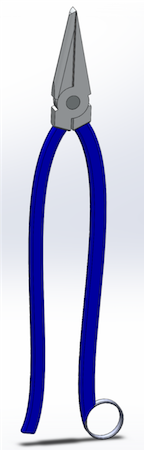

Our mission is to design and manufacture a novel zip-tie cutting and retention device for use during an EVA. We dub our design: The Lion Cutter.

The mission co-leads are Tejit Pabari (SEAS ‘21) and Christopher Fryer (SEAS ‘19). The team members are: Yuanxia Lee (CC ‘18), Garrett Harrison (SEAS ‘21), Megan Noga (SEAS ‘20), Henrique Monteiro (SEAS ‘21), Mitchell Miya (SEAS ‘21), David Alvarez (SEAS ‘21)

We spent weeks brainstorming designs and drawing rough schematics of our ideal device design, and submitted our finished proposal to NASA. Here are some preliminary CAD drawings that we included in our proposal:

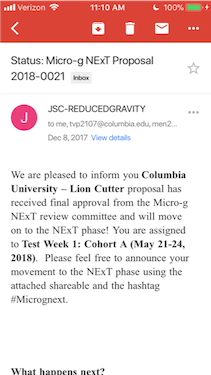

In December we received the amazing news that our proposal had been accepted!

We will now join 21 other undergraduate teams at the Neutral Buoyancy Lab in the spring!

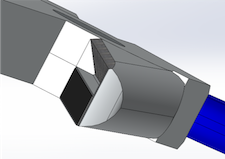

We are modifying our design to include a spring-locking mechanism, which will keep the device closed during zip-tie retention without needing for the astronaut to continually hold onto the device. Here is a preliminary CAD drawing of said modification:

We hope to begin manufacturing soon.

-Chris and the entire Micro-G team

CSI’s Outreach team has taught over 200 NYC middle schoolers at MS 302 and MS 126 this past month, in partnership with the Sophie Gerson Healthy Youth Foundation and the Columbia Engineering Outreach Office in its “Engineering Speaks” outreach lecture series.

We enjoyed sharing about the history of aerospace, the basics of space science, and the cool new innovations and companies in aerospace today. Most of all, we enjoyed seeing the students’ enthusiasm and curiosity about aerospace. At the end of each lecture, we had a paper airplane competition to illustrate aerodynamic principles firsthand. We were blown away by their engineering skills - there were airplanes that traveled all the way across the auditorium, airplanes that boomeranged back to their owners, and more! Each time, students would linger afterward to ask us follow-up questions and to tell us about their future plans to become pilots or scientists. It has been a truly rewarding set of experiences, and we can’t wait to continue to inspire and be inspired by the next generation of space engineers and scientists in spring.

– Leena Chen

This Saturday was our third time participating in CU Splash, a day-long event for high school students to learn topics outside of the classroom. We taught a course called “Intro to Space Exploration,” where we introduced basic orbital mechanics, propellants, space history, and challenges in space.

For many of our students, this was their first exposure to space science and aerospace engineering.

In addition to the science, we discussed commercial space companies, international space industries and modern innovation like suit ports and inflatable space modules.

We held two sections and each had 40+ students. We had lots of fun inspiring the next generation of space travelers.

Thank you to Leena, ShaSha, Caleb, Tejit, Lily, Megan, Chris, and Garrett for making this day of space learning possible.

– Lily He

This is an exciting time for the Micro-g team. We’ve been hard at work over the past couple of weeks, planning and running our outreach events, making design improvements, and even prototyping!

A few weeks ago, we met our advisor from NASA (via web video), who will be helping us through the final stages of our product development and testing. Before the meeting, our mission co-leads 3D-printed the first prototype of the sample tube in our device.

AsadAndMike.jpg)

We were even able to take a photo of the full team, thanks to a little help from web video!

TeamPhoto.jpg)

Lately, our design improvements have been focused on optimizing the turbine driving the drill using a new “planetary gear” system. Check out one of our sketches below:

Sketch.jpg)

We’ve also begun prototyping the Iris Mechanism at the bottom of our drill. The mechanism contains many small parts, so printing it was a little tricky. However, our second attempt looks much more promising.

OpenIris.jpeg)

ClosedIris.jpeg)

We’re going to continue to improve our design, and soon we’ll start machining our drill!

Our team has been having an incredible amount of fun planning and running our outreach events over the past few weeks. We’ve been spending a lot of time at various kids’ science events, teaching them about space technology and our project, and encouraging them to go into STEM fields so they can also contribute to our exploration of the final frontier! Here are some of the highlights from our outreach events at the Intrepid Air and Space Museum, Liberty Science Center, and Manhattanville Community Center.

On Friday, February 24, we ran a workshop at the Intrepid’s Kids’ Week.

IntrepidWorkshop.jpg)

We talked to them about parachutes—how they work, how they’re made, and their role in bringing astronauts back to Earth safely. Then, we guided them through the process of making their own parachutes, and everyone had a blast!

Parachutes.jpg)

On Saturday, February 25, some brave souls among us woke up at the crack of dawn to make the trek to Liberty Science Center in New Jersey. They explained our project to the kids, and demonstrated basic principles of energy by simulating asteroids hitting planets and making craters.

LSCWorkshop.jpeg)

It got a little messy, but everyone loved it!

Finally, this past Friday, March 4, we ran our first of four workshops at Manhattanville Community Center. The parachute activity was repeated to great success.

Manhattanville1.jpg)

Stay tuned for more updates!

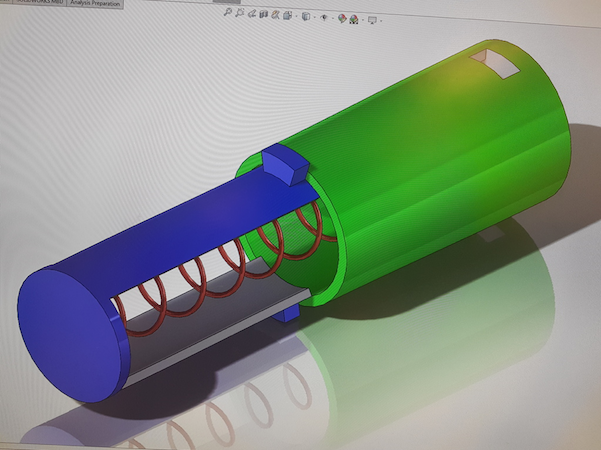

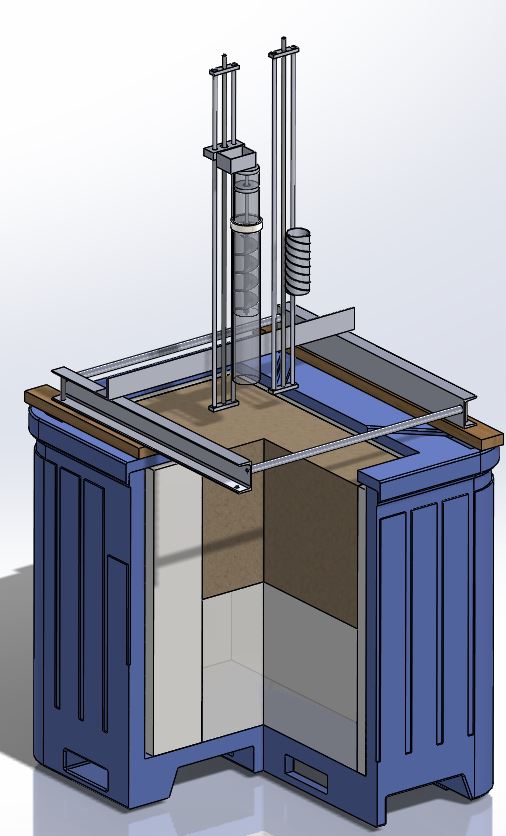

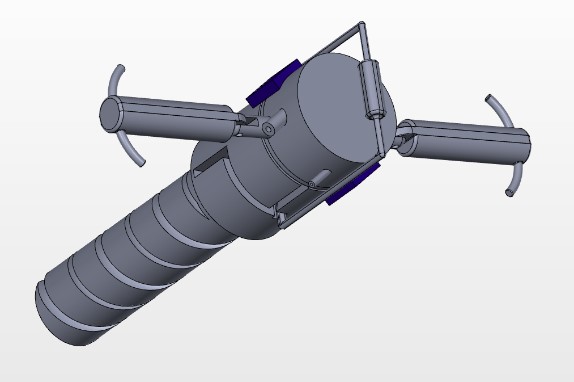

We’ve continued making great progress on our Mars ice drill, the Lion Piercer. Our drill system will feature two subsystems, an overburden extraction auger to clear a path to the ice, and an ice extraction drill that extracts the in-hole ice for melting. Both drills utilize cylindrical casing in their drilling mechanism.

Furthermore, both drills will be moved by a gantry system mounted atop our simulated ice box environment. System mock-up:

Our upcoming deadline is the Mid-Project Review on April 2nd, when we will be submitting a video of our drill prototype in action, featuring its mounting system, control interface, and operation excavating overburden and ice. In addition, we’ll be submitting a written document describing our development process and our integration and testing plan.

Ad astra!

-James

Our LEO Lion design has been selected to move on to semifinals! LEO Lion is a commercially-enabled LEO / Mars habitable module, featuring innovative technology and new commercial applications in space. Our next deadline is the Mid-Project Review on March 16th, when we will be submitting a 6-page mission concept and analysis plan to the National Institute of Aerospace and NASA for approval.

Our Lion Piercer, a device to extract subsurface water on Mars, is also making progress. Though we were not ultimately selected as finalists in the RASC-AL Mars Ice Challenge, we have received funding to begin building Lion Piercer. We potentially have the opportunity to re-enter the competition if we submit a Mid-Point Progress report on April 2nd.

-Leena

If you’ve followed CSI news, you’ll know that last year’s Micro-G team killed it. The team entered NASA’s design challenge to build a near-Earth asteroid anchoring device, and after months of work produced the “Lion Claw”, which passed with flying colors during testing at NASA’s NBL.

We’re very excited to introduce this year’s Micro-G team! We’ve already been hard at work on our mission since September; in fact, we’ve been working so hard that news updates have taken a backseat to our constant efforts to improve our design. But not to fear! Without further ado, we’d like to present Micro-G NExT 2017!

Our logo, designed by Maggie Fei

It was September, and this year’s Micro-G team clearly had a lot to live up to. Since Columbia’s previous team had already conquered the asteroid anchoring device challenge, we chose to enter a different Micro-G mission: the Subsurface Sampling Device challenge.

NASA is currently working on systems to take humans beyond Low Earth Orbit to explore the solar system. Some of the destinations of interest are celestial bodies with milligravity to microgravity.

A sample type of interest to scientists is a subsurface sample. Subsurface samples can showcase the history of the body and describe its internal structure.

Our mission: To design and manufacture a device that enables an astronaut to obtain a subsurface sample (core sample) in microgravity.

Our mission is co-led by Asad Saleem (SEAS ’20) and Mikhail Karasev (SEAS ’20).

The team members are:

Alex Kim (SEAS ’20), Ben Kepecs (CC ’20), Francesco Zampetti (SEAS ’18), Karina Yeh (SEAS ’20), Kevin Le (SEAS ’20), and Robert Kydd (SEAS ’18).

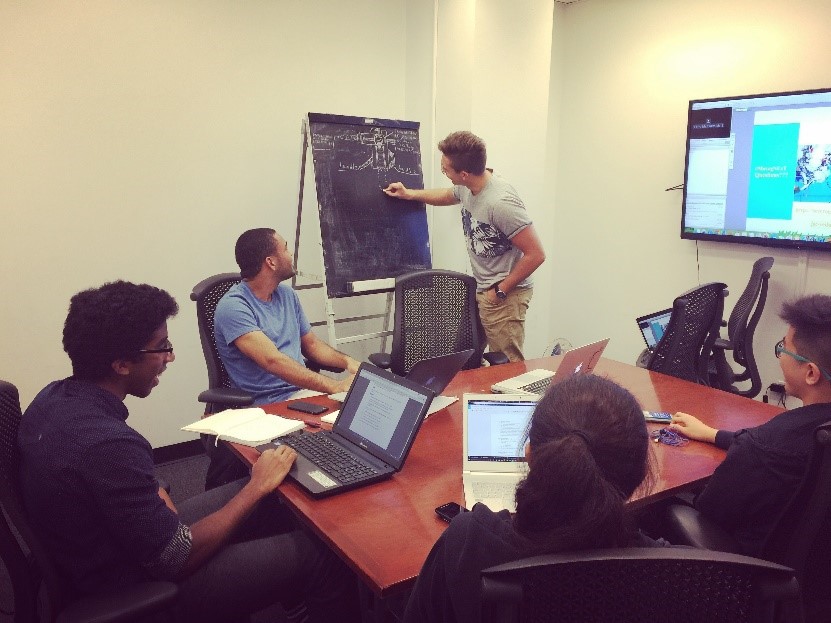

Our first step was to draft and submit a design proposal to NASA. We spent several weeks brainstorming drill designs, filling chalkboards with designs, ideas, measurements, and the inevitable modifications.

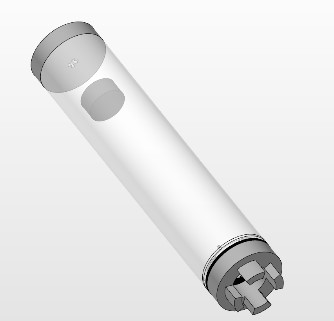

Complicating our design were the criteria that the device had to be able to drill around a cylindrical core sample of either sandstone or sand, and also somehow seal at the end to prevent the sample from falling out. We took some inspiration from already extant ice-corers, which are designed to drill down into polar ice to collect core samples. We decided that a pneumatically powered device was our best bet to drill through sandstone, and discovered an interesting mechanism that we could use to close the end of the collection tube, an Iris Mechanism. After a lot of work, we finished the first draft of our design and submitted our proposal. Check out the animation below showing how our device works, using a model imported from our CAD assembly.

Finally, in December, we received some great news: our proposal had been accepted!

This meant that we would now actually manufacture our device and test it at NASA’s Neutral Buoyancy Laboratory in Houston, Texas, alongside teams from 29 other universities.

Now, we’re putting the final touches on our design, and we hope to start manufacturing it soon.

Some of our latest CAD models.

Left - the version for sandstone collection; right - the sample tube; below - the model for sand collection.

We are also coordinating our outreach activities at Liberty Science Center, the Intrepid Air and Space Museum, and various schools throughout New York City. We are very excited about these events and the progress that we have made, and we hope that you continue to follow us in our mission!

-Ben and the entire Micro-G team

Well, if you follow us on social media you’ll know that we went to Houston last week to test our asteroid anchor. Without further ado, here’s our mission debrief:

We had started this process in December with our initial concept, but quickly realized that our design was impossible to manufacture. Starting anew, we had another design and prototype by March - only to see that it had failed to hold the 10 lbs of force during testing.

Into this week were betting on a new design and scrambled to manufacture and test it. Kristina and Tamás, our team leads, had many a sleepless night over the anchor. We had only tested the anchor underwater a few times before making the trip to Houston. Although the anchor had worked in our underwater test, we were still understandbly nervous about the anchor - would it work in the NBL? would it pass NASA’s stringent safety inspection?

But to our delight, our anchor did pass - in all respects. On our first day in Houston, we had our Technical Readiness Review, in which we proved to NASA specialists that our tool was safe for use in the NBL. After some filing of sharp edges and softening wire tips, we were good to go.

The second day in Houston was our test day; we were scheduled for a 9:10 a.m. test, though in actuality we started ten minutes later. Jordi was TC (Test Controller), and directed the divers in realtime on how to operate the tool. I also livestreamed the event on our Facebook page; it’ll also be on YouTube soon.

We held at least 30 lbs of force, even though NASA only required us to hold 10 lbs of force. The divers themselves even said that this was one of the strongest designs there. With the anchor only half-deployed (only the bottom plates deployed), we held the requisite 10 lbs of force. Suffice to say, we’re pleased with how well testing turned out!

We also won the social media prize, and got a special tour of Building 9, which is the Space Vehicle Mockup Facility. We touched the actual ISS mockups that astronauts used to train!

First of all, thank you to everyone who contributed to this mission. Kristina and Tamás were amazing team leads, both of whom entirely determined the success of the project, and deserve every accolade. Brian also is a standout with SolidWorks, and Jordi is our finance master - without which we wouldn’t have had the money to make this trip possible.

Meanwhile, check out our vlog series on YouTube to get a sense of what our trip was like.

Finally, we hope to continue the Micro-g NExT program next year. We had a blast doing it, and Kristina and Tamás will be able to stay on as advisors for future participants from Columbia.

-Julia, Micro-g Logistics/Everything

Hey y’all,

It’s an exciting week for us on the micro-g team here at csi! We’ll be going to Houston next week to test the LionClaw, our design for a microgravity anchor. The anchor would theoretically be used by spacecraft visiting near-Earth asteroids, which are essentially asteroids closer to us than Mars is (roughly 50 million miles or less; space scales are weird). Because these asteroids are so small, the amount of gravity we would experience on them would be negligible, so we need an anchor to keep our astronauts on its surface.

NASA has generously provided us and other undergraduate teams the opportunity

to test our anchor at the National Buoyancy Laboratory (NBL). The NBL is a

giant pool where astronauts run simulations or test equipment to mimic the

weightlessness experienced in space and on asteroids! We’re extremely excited

to test our design there!

We’ll be keeping you updated on our progress in Houston as we test the design, but for now, we’ll be working hard in Columbia’s excellent machine shop and makerspace. If you’re in the area, feel free to come and check out our design if you have any questions or would like to see it for yourself! Columbia has kindly provided the resources that have made this design possible, so it is the least we can do in return to the Columbia community.

Look out for Kristina, Tamas, or Brian (pictured below).

-Jordi

I’ve wanted to make this post for a while, but life and finals got in the way. I finally found the time to write this up, exactly a month after the balloon launch.

First of all, thank you to everyone that contributed to this mission. We couldn’t have done it without you all.

The balloon was launched on April 16th, 2016 just before 4pm EST near Prattsville, NY. We had initially planned for the launch to be before noon to make recovery easier, but delays and technical issues pushed the launch time back.

Over the course of almost three hours, the balloon rose at a rate of 5 m/s or ~16 ft/s, reaching a peak of 32948.88m or 108100ft at about 6pm EST.

The balloon landed in the backyard of a farm house around 6:44pm. It landed in the middle of a lawn right next to a road, resulting in a very easy recovery. We were very grateful for this, as by the time we reached the payload it had gotten dark. Landing in a more difficult location would have required recovery on a different day.

The maximum altitude of our balloon is rank 88 on arhab.org

Having multiple possible launch locations was crucial - launch sites became unavailable due to weather and logistics changes.

We need a smaller tank for helium transportation. We had to rent a van to carry the large tank, which was an inefficient use of funds as it could only carry 2 people. Using two smaller tanks would allow us to carry them in an SUV, which can fit more people.

I thought the APRS GPS tracker (the radio one) wasn’t working because it wasn’t showing up on the website. However, I was able to verify with my Baofeng UV-5R and APRSdroid’s packet decoder that the radio was, in fact, working. I later determined that, because we were launching in the mountains, the radio signals weren’t getting to the nearest repeater. The balloon showed up on the website shortly after launch.

The ground winds were absolutely brutal for the launch. Considering it was the first launch for most of our crew, they handled it remarkably well. The winds finally died down towards the end, enough for us to get a clean launch.

Since we didn’t have a mass flow meter to measure the amount of helium (we were quoted $2500 for one from Alicat), we had to use a scale to determine the lift force. A cheap luggage scale/fish scale worked well enough to ensure we didn’t underfill the balloon, but by launch we had to wing it to catch the break in surface wind.

The SPOT GPS tracker we had worked for going up (under the altitude limit) and showed up a couple times during the descent but didn’t work for the landing. This is interesting, especially since it’s usually the radio that doesn’t survive the landing.

We accidentally taped over the ozone sensor poking out of the box - this is my fault for not familiarizing the crew with the equipment and payloads; I might have even taped over it myself. We still collected data, but I’m not sure how accurate or reliable it is.

We need to launch much earlier next time ensure we can recover before sunset. This will get better with more preparation and experience.

The GoPro battery ran out early (we had the cheapest model) so we only got footage up to ~70,000 ft. We’re looking into acquiring a better GoPro along with a battery backpack.

We will start going through the data more thoroughly now, especially with more time in the summer. We’ll post any results or findings here.

BWOG wrote an article about us! Read it here

We released our Youtube video of the launch, watch it here

The Columbia University Facebook page wrote a post about us, read it here

With a successful launch under our belt, we can look forward to doing more exciting and ambitious things!

We need to start looking for additional funding and future mission objectives. If you have any suggestions, please feel free to contact us through email or social media.

Thanks, Jake Lee

We’re launching our balloon tomorrow! We’ll be launching at 10AM from Prattsville, NY.

You can track the balloon here.

A quick run-down of the mission:

We’re looking forward to a great launch!

Follow us on twitter to see live updates. There is a button at the bottom of the website.

p.s. The rockets team is launching tomorrow too!

-Jake

Redesigns are underway on our asteroid anchor. Tomorrow (April 8), we will be manufacturing our design changes in the Mechanical Engineering Shop. The Columbia Daily Spectator will also film a behind-the-scenes video of our manufacturing process. Stop by at 1 p.m. with your CSI shirt to appear in our video!

-Julia

Our mission proposal “Path to Deimos” was selected as one of twelve finalists to present at the annual RASC-AL Forum in Cocoa Beach, Florida this June! This is incredibly exciting - especially being the first time ever for Columbia to participate - and I couldn’t be prouder of what our entire team has accomplished. A big thank you to our project advisor Professor Mike Massimino for his invaluable support and guidance, and congratulations to all members of CSI for another job well done.

Our next major goal is to submit both a final technical paper and an oral presentation by June 2. The final paper will be 10-15 pages in length, fully implementing all the specific technical details and diagrams we laid out in our mid-project review, and our oral presentation will highlight key aspects of our mission and fill a 30 minute time slot at the Forum. In addition, we’ll also have to prepare a trifold board that summarizes our mission for the poster session. Based on how well we do at the Forum, two of the top-winning teams will be invited to yet another technical conference (e.g. AIAA Space) to share their concepts!

As we craft the two components of our final project in the coming weeks, you’re welcome to join the RASC-AL team anytime - just post a message in the Slack channel or reach out to any current member of the mission team if you’re interested. The Forum will take place from Tuesday, June 21 to Friday, June 24; more info on travel logistics to come.

-James

NASA JPL celebrates the successful landing of the Curiosity Rover on Mars

A few updates for the end of March:

Thanks, -Jake

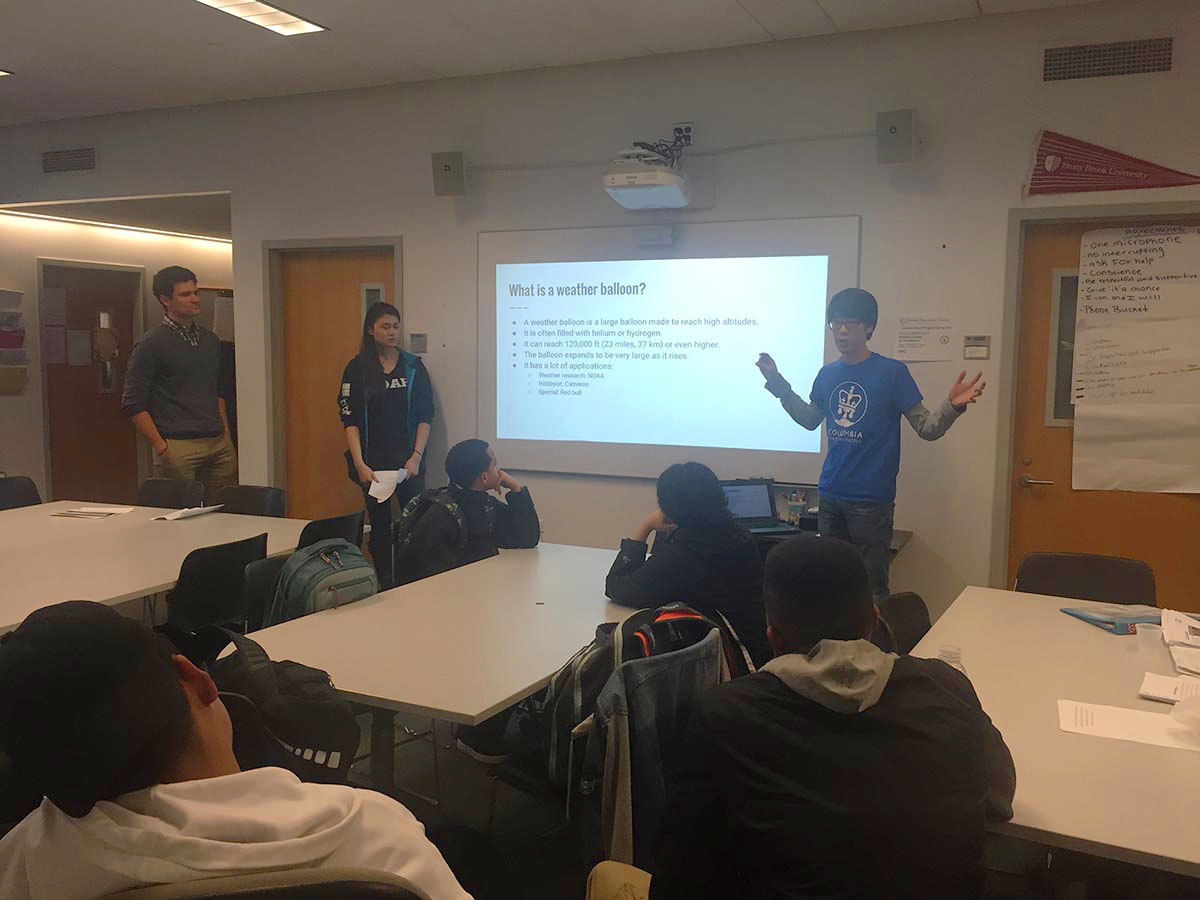

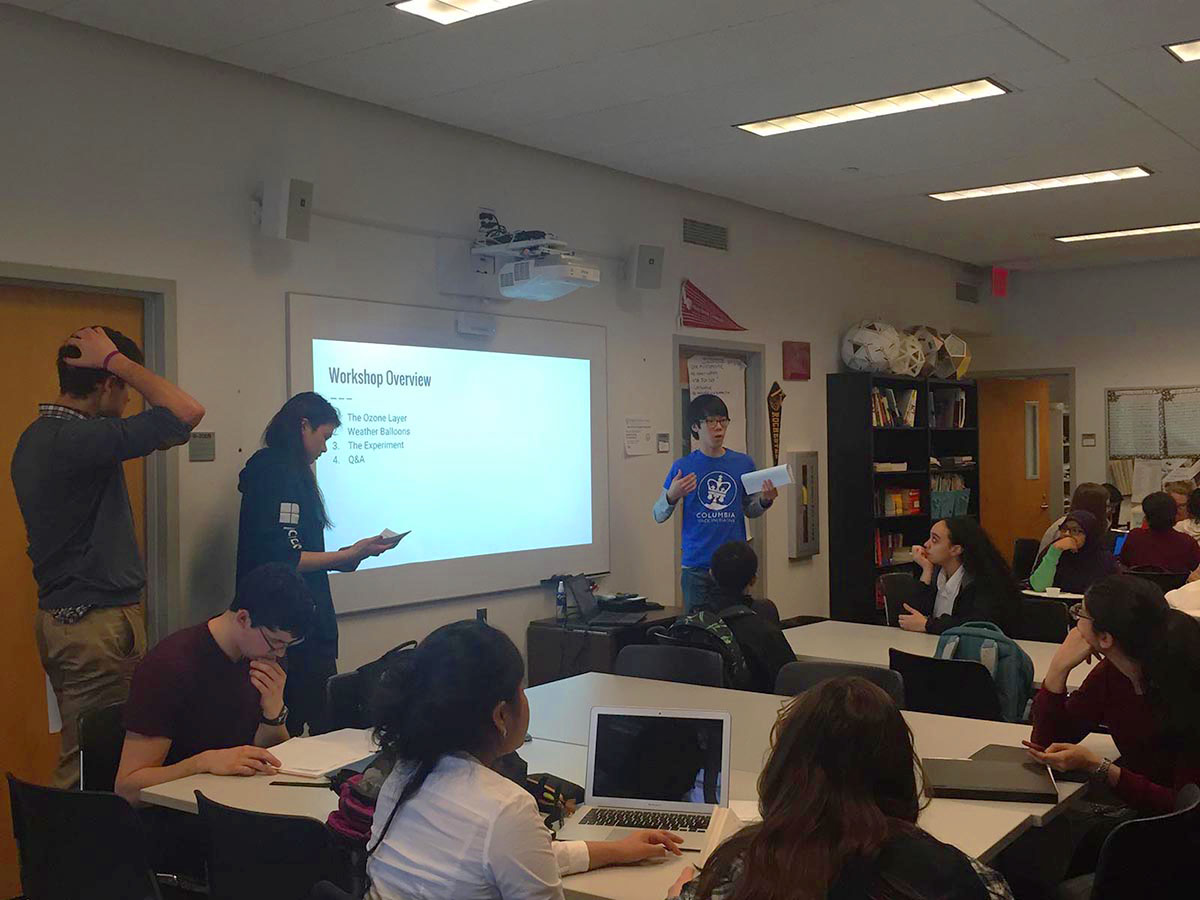

Today, we had the pleasure of running a workshop with the Double Discovery Center. Titled, “Exploring the Atmosphere with Extreme Balloons”, the one hour workshop sought to talk about the importance of the ozone layer to life on Earth, the applications of high-altitude weather balloons, and combined the two subjects in an interactive experiment design discussion.

We really enjoyed doing the workshop, and we would like to thank the DDC for hosting us. We hope that we will be able to come back after our launch in mid-April and share some science and fun from our project.

Any other organizations that are interested in hosting a similar workshop can contact us at our contact page.

The resources used in the workshop, including the presentation and the accompanying notes, are available on the balloons mission page.

It’s 6:55 p.m. (EST) and we have submitted our Technical Equipment Data Package (TEDP) to NASA. It’s 40 pages long and written with lots of love from everyone on the team.

Although submitting the TEDP was a great success, we do have some unfortunate news: our asteroid anchor design doesn’t quite work. We have tested the design and found that the anchor does not withstand the full 10 lbs of force required by the NASA design rules. We’re working on redesigning the anchor, but with only about 40 days before we head to Houston, we don’t have much time for major design changes. It’s not a huge issue though - we’re relatively certain that our mechanical reasoning is solid; we just need more surface area to interact with the regolith.

-Julia

We submitted our mid-project review to the RASC-AL competition today, after making it to the second round. A big thank you to all the project team members who dedicated time over their spring breaks to work on our report. We will hear back from the competition judges on April 1st as to whether our team’s been chosen to proceed to the final round of the competition, which entails presenting a full 15-page technical paper at the RASC-AL Forum in Cape Canaveral this June! Stay tuned!

-James

The “Path to Deimos” mission patch:

Last few weeks have been super manufacturing-intense! Coming off of spring break, we have most of our body and the inside mechanism ready. We have tested and scrapped some parts and designed and made new ones! Mistakes in machining are inevitable, so we had to remake the plates and the cone, which we finished last week. Next big milestone is the TEDP report due next week!

-Kristina

We’re making some steady progress.

We’ve managed to acquire helium thanks to Jordi! Thank you Jordi!

We finished maintenance on our old electronic equipment. We will begin work on the 10DOF sensor from Marco (thanks!) and the ozone sensor whenever it comes in.

This Saturday (so, tomorrow) we will be working on the GoPro mount as well as the 10DOF sensor.

We’ve also updated CCSC on our details and such, so we should be getting some of our equipment soon!

We’re on the final stretch, hopefully we can get almost everything ready to go by the end of this month. No, we WILL get everything ready to go by the end of this month.

-Jake

Our abstract “Path to Deimos” was selected to continue onto the next stage of the RASC-AL competition! We are now in full gear working towards our next goal of submitting a mid-project review paper by March 18, 2016. The mid-project review will be around 3 pages in length, with 2 pages of text that describes the mission concept and analysis plan, and one page with information graphics and calculations. Based on that, just one more round of cuts will be made before it’s decided which teams get to attend the RASC-AL Forum at Cape Canaveral, FL in June.

We’ll be recuiting new members to join the RASC-AL team in the coming weeks - stop by one of CSI’s general body meetings or reach out to any current member of the mission team if you’re interested!

-James

With the start of the new semester, we’re welcoming new members to the mission. Here’s how you can get involved, from least to most participation.

Thanks everyone for the interest, we’re trying to launch by early April. With your support, we can make this a reality.

-Jake Lee, Balloons Flight Director

We submitted our abstract to the RASC-AL competition today. Our abstract proposed a mission that would deliver a crew of four humans to Deimos, the smaller and outer of Mars’ moons, as a stepping stone to reaching Mars. We will hear back from NASA on February 5th as to whether our abstract’s been chosen to proceed to the next round of the competition, and will update you then about our results. Stay tuned!

-Julia

With the completion of our GoPro crowdfunding campaign, we have now acquired all of our payloads!

Here’s a quick look at what we have left to do:

-Jake Lee, Balloons Flight Director

Our sponsor, W2AEE Columbia University Amateur Radio Club, has submitted the order for a SPOT Trace so we can better track our payload! Many thanks to Eugene Lee for organizing our partnership with W2AEE!

-Eugene Lee

The Force was strong with the Columbia Space Initiative this past December, as a crew of 9 space lions joined members of FSAE to see the latest installment of the Star Wars saga in stunning IMAX 3D. Arriving in Times Square for our showtime at the bizarre hour of 2 in the morning, the Star Wars gang stayed sharp with the help of some Jedi mind tricks and caffeine. As we entered the theater with the throngs of New Yorkers fitted in Jedi garb, one couldn’t help but feel the Force pulsating in the air.

Indeed, The Force Awakens turned out to be one of the most incredible cinematic adventures for all of us, replete with moments that make the midichlorians tingle down your spine. The rowdy 2am theatergoers gave plenty of thundering ovations, and in hindsight the whole experience was more a Knicks game than a movie. Though not as scientifically or engineeringly detailed as, say, The Martian, The Force Awakens was an awesome reminder of what space stands for in the imagination of so many people around the world, and the type of thing that got many of us at CSI curious to learn about space in the first place (though rocket science isn’t as easy as they make it look like). Anyways, as we enter our second semester as a club, stay tuned to our many mission pages as we finish… what we started!

-James

Good news! We’ve submitted our 60+ page proposal to NASA today for the Student Flight Research Opportunity (SFRO). Many thanks to all the team members who’ve contributed to the creation of this proposal! Our cubesat experiments will test the tensile properties of glass, and the viability of certain radiation shielding on commercial electronics. We’ll keep you updated on our results.

-Julia

We have submitted our preliminary design to NASA. The final design is an assembly of around 9 parts: the cone, shaft, 5 plates, piston, and blocking bar. The cone piece that is the first part to make direct contact with the surface is threaded for ease of penetration. The shaft serves as the housing for the piston and the plates attached by individual hinges. A person pushing on the piston activates the plate assembly and they slide out of their holes and grip the m_barnes. Our design underwent many changes during the brainstorming procedure. Our inspirations were river anchors, screwpile drills, and the fractal design used on the Rosetta comet.

Kristina, Co-Head of Micro-G Team